WhatsApp)

WhatsApp)

Theory and Practice for . Jar, Ball and Pebble Milling . ... Usually, however, a ball mill is referred to as one that uses steel balls as grinding media, ...

Video embedded· How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder.

CNC Milling: Introduction to cutting tools . ... Choosing flat end mill vs. a ball end mill will determine the characteristics of the tooling marks (or lack thereof) ...

Cement mill Wikipedia, the free encyclopedia. Most cement is currently ground in ball mills and also vertical roller mills which are ... In the case of some ...

Autogenous and Semiautogenous mills. ... or an immediate size for further grinding in a ball mill, pebble mill, or a VERTIMILL® or a stirred media detritor ...

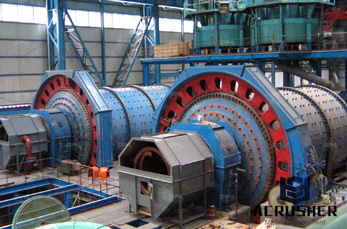

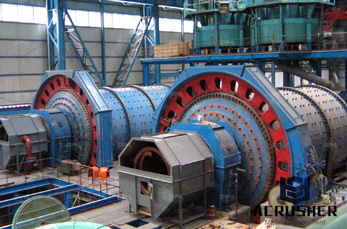

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

Mining Industry: What is the difference of ball mill, attrition mill, sand mill, and small media mill? Such as media size, tip speed.

Secondary crushing: worth the cost? Ausenco. stagecrush, rod and/or ballmill circuits. The concept was twostage AG and ballmill circuit in North.

Jul 15, 2011· I am researching the differences between making or shall I say refining chcolate and ingredient mixes on a ball mill refiner versus roller refiner process.

Contact Union Process for the answer to your toughest high energy ball milling questions. We have the expertise experience to provide the help you need

Fine Grinding Technology for Mines and Concentrating Plants: "Stirred Mill" vs. Ball Mills ... The horizontal stirred mill approach for grinding rocks, ...

Jan 31, 2008· Video embedded· I put this ball mill together using a second hand 12 volt motor (20NZ) and a few old scraps from around the workshop. The tin holds 1 litre. I .

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Find 29 2nd Hand/Used Ball Mills in Stock Now IPP. ippe Ball Mills Pebble Mills – Basically a horizontal tube with balls or stone grinding media, that grinds ...

Comparison of Energy Efficiency Between Ball Mills and ... It is difficult to compare the energy efficiency of the regrind ball mill with the IsaMill ...

Ball Mill Ball mill is suitable for Grinding and Size Reduction of Quartz, Feldspar and China. Clay to form slurry for Ceramic Industry. The mill is designed with ...

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

A typical ball mill has an L/D ratio of :1. Ball mills are filled with spheres or other shapes made of steel or ceramics; or with

Feb 14, 2009· RecrystallizedRocket. Loading ... Working principle of Ball Mill /ball cement milling machinery .

between SAG and ball mill hardness for the majority of the test work data but the correlation is too low to be useful in sizing a SAG mill from only a BWi measurement.

Cement grinding Vertical roller mills versus ball mills ... to the ball mill system and has increased its share of the ... OK mill and the retention time in the ...

ball mill vs sag mill YouTube 10 Dec 2013 ... difference between a sag mill and ball mill. Strongly recommend you to contact with us through online service!

Ball Mill Ball mill is suitable for Grinding and Size Reduction of Quartz, Feldspar and China. Clay to form slurry for Ceramic Industry. The mill is designed with ...

WhatsApp)

WhatsApp)