WhatsApp)

WhatsApp)

Chemical milling or industrial etching is the subtractive manufacturing process of using baths of temperatureregulated etching chemicals to remove material to create ...

Brass is a metal composed primarily of copper and zinc. Copper is the main component, and brass is usually classified as a copper alloy.

Whole grains cause tooth decay. In part because of their phytic acid level, in part because of toxins in the bran.

The Pulp and Paper Making Processes ... A typical layout of a mill using the kraft chemical pulping process is shown in ... Steps in the Pulp and Papermaking Process

Photochemical milling, also known as "chemical milling" is a process for producing usually small flat parts from metal foils. The process has these steps: 1. Preclean foil in preparation for photoresist application. 2. Apply photoresist, usually dryfilm, may be liquid.

Port Manteaux churns out silly new words when you feed it an idea or two. Enter a word (or two) above and you''ll get back a bunch of portmanteaux created by jamming ...

CHEMICAL MILLING AND THE REMOVAL OF ... WORCESTER POLYTECHNIC INSTITUTE ... and forging are not the only steps in the complete process. Chemical milling must be ...

Sep 12, 1978· Chemical milling processes which employ a series of masking and metal removal steps. Apparatus for orbiting the workpiece in a prescribed manner about ...

1 1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of ...

Apr 04, 2016· How to Acid Etch Steel. Because copper and zinc have gone up in price, many artisans who etch designs in metals have turned to etching steel. Although not ...

Jul 12, 2006· This should have a higher Kt than the chem mill step. ... but also for the production of valuable tooling in the larger manufacturing process. Download Now.

Citation data is made available by participants in CrossRef''s Citedby Linking service.

In Colorado, researchers are fighting nasty, deadly, stubborn bacteria with chitosan, a material derived from shellfish shells like lobsters, crabs, and shrimps.

chemical milling process, ... construction appears more feasible by chemical milling than by ... cut may be performed by steps on large ...

This is a reasonably safe, easy to make, high powered flash powder, suitable for use in electrically triggered pyrotechnics stays reasonably stable under ...

mapped for chem mill: The chemical milling process selectively removes material while maintaining structural strength where ... Chem milled fuselage skin for ...

Largest electronic, electrical and industrial products catalogue and data library online in Asia. Offering secure online ordering with same day despatch.

MMEX Resources Corp, a developmentstage company focusing on the acquisition, development and financing of oil, gas, refining and infrastructure projects in ...

This process comprises the steps of depositing a suitable maskant which is resistant to the chemicals used in chemmilling on a backup sheet such as thin plastic ...

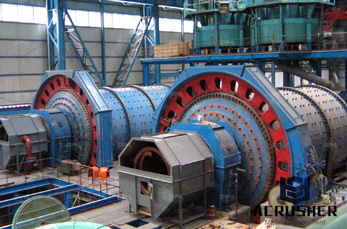

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material.

Milling is the most common form of machining, a material removal process, which can create a variety of features on a part by cutting away the unwanted material.

Steps in an Analysis Define the Problem Select a Method Obtain a Representative Sample Prepare the Sample for Analysis PerformAny Necessary Perform the Chemical ...

Antioxidant Activity of Tocopherols, Tocotrienols, and γOryzanol Components from Rice Bran against Cholesterol Oxidation Accelerated by 2,2''Azobis(2 ...

Chemical milling is the process of removing large amounts of metal by means of chemical etching. All metal types and shapes are candidates for chemical milling, especially .

WhatsApp)

WhatsApp)