WhatsApp)

WhatsApp)

Calculate Ball Mill Grinding Capacity. Previous Next. View Larger Image; The sizing of ball mills and ball milling circuits from laboratory grinding tests is ...

A useful and simple equation describing the grinding momentum is M x ... TYPE OF MILL MEDIA SIZE RPM TIP SPEED (fpm) Ball Mill ... The critical speed of a ball mill ...

Comminution efficiency is a technical term that relates some measure of the output from a comminution machine to the energy input into it. The term has usually been ...

Ball Mill Instruction Manual (PDF) BICO Inc. The Bond Ball Mill is a small universal laboratory mill used in calculating the Because ofvaxiations in ball size ...

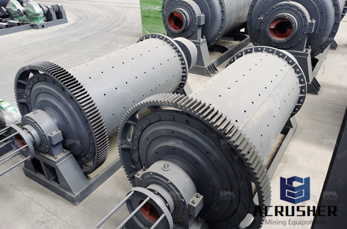

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all ...

Knowledge and technology count, size the mill right first time Correct sizing of grinding mills requires indepth knowledge and experience of crushing and ...

Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills.

Standard Reach Ball. ... Solid Carbide 2 flute ball end mill .021 Shank Size 1/8 x 11/2" Cutting Tip .021 ball Cutting length .063 Shank Diameter: ...

retSCH Planetary Ball Mills are used for the pulverization of soft, ... 6 x 20 mm ZrO 2 2 ... of size reduction of the Planetary Ball Mill.

Planetary Ball Mill PM 100. Function Features; Downloads; Order Data; ... Batch size / feed quantity* max. 1 x 220 ml, max. 2 x 20 ml with stacked grinding jars:

STEEL BALL MILLS : j ... 331/3J6 STEEL BALL CHARGE MILL SPEED 50% OF CRITICAL iNc) ... Mill Size (Dia. X . Length) 15"x21" 21"x28" 2'' X . 3''

Design and Optimization of Ball Mill for ... Rs. 6 / kWh gives annual saving of x 106T x Rs ... equations showed top side steel ball size M = 127 mm; mill speed ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

ISIZE Media Sneaker ISIZE MEDIA SNEAKER ... Lonzo Ball ZO2 201706 ...

2 all ills all ills 3 Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft. x 8 ft. with 75 HP to 30'' x 41 ...

Find great deals on eBay for Ball Mill in Metalworking End Mills. Shop with confidence.

Ball mill is used to fine grinding the ceramic materials. It is suitable for large building ceramic, sanitary porcelain, electric porcelain, ceramic tile, clay roof ...

Ball mill rpm calculation on size – Ball mill rpm calculation on size. Gulin supply Mining and construction equipment for mineral handling.

We sell all types of Grinding Mills, Rod Mills, Pebble Mills, SAG Mills, Ball Mills, if you are looking for partial or complete replacement for all the ball mill ...

Ball size distribution for the maximum production of a narrowlysized mill product Ngonidzashe Chimwania,⁎, François K. Mulengab, Diane Hildebrandta

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

The optimum composition of the makeup ball sizes in ball mills is presented. • The effect of various factors was investigated via a grinding circuit simulation.

· typical size ball mill Nsser ... For a typical end mill weight from the single comminution event that are finer than size x, suggest that even in ball

WhatsApp)

WhatsApp)