WhatsApp)

WhatsApp)

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill ...

grinding mill filling calculations . Calculate Ball Mill Grinding Capacity ... Then, the optimal mass ratio of ball to powder in ball mill is ...

what is the optimum rotation speed for a ball mill... barricading the mill, optimum milling time, optimum media load, ... ball filling ratio, and mill rotation speed ...

Ying [8] studied the influence of the mill''s rotation rate, the ball filling ratio,. Performance calculator for ball mills based on dry milling method .

Grinding Media Ratio In Cement Mill ... 10 Jan 2014 ... ball mill for cement grinding able for large grinding media ... the L/D ratio, ball charge filling ratio, ...

The influence of several grinding parameters such as charged material volume, ball filling ratio, and mill rotation speed on energy efficiency of ...

Filling ratio of grinding material or ball to powder ... Calculate and Select Ball Mill . calculation for cement mill circulating load ratio ball mill ...

a)Idle running (without grinding operation and materials) 37hours. b)Install 1 / 3 of the grinding operation of 35 hours.

Ball Mill Group Calculation Feed capacity → Mill dimensions Filling ratio ... derivation to calculate critical speed of ball mill . design calculation of ...

filling ratio for a ball mill – The QA wiki. In this,the filling material is replaced by using suitable placebo (Lactose,PEG) along with micribological .

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

Effect of ball mill grinding ... Wet Grinding of Sodium Feldspar in a Stirred Ball Mill sizes decreases with an increasing grinding times, ball filling ratio, ...

My Tech. Report on Ball mill. ... of ball mills: batch ball mill and continuous ball mill with ... charge ratio to the volume of mill is known as {Filling ratio} ...

the ball mill ball filling ratio of grinding mill. the ball mill ball filling ratio of grinding mill_Internal components for ball mills Christian ...

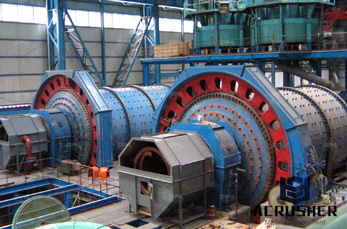

Ball mill is the main equipment of ore dressing process, and it is widely used in mining, metallurgy, building materials, refractory, cement, chemical and thermal ...

ball mill calculation ... Ball Mill Group Calculation Feed capacity → Mill dimensions Filling ratio (3045%), Mill ... design calculations of ball mill. ball ...

ratio of South African style SAG mills, ... showing the length and filling of the mill, ... cooling of the balls. When the ball is worn to the point where the

The optimal operating speed depends mainly on filling degree, ... The water to lime ratio for the ball mill slakers is 5 to 6 parts . View quotes>>

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls ...

calculation of ball filling ratio in grinding mill. Ball Mill Filling Ratio Binq Mining. This page is provide professional calculation of ball filling ratio in ...

Ball mills conditions such as ball size, ball filling ratio, mill diameter,. View quotes>> Effect of Ball Size and Ball to Powder Ratio Variation on Crystallite .

Feb 26, 2013· Standard Media Filling Ratio for a Ball MillcompanyNews. Stainless steel balls are often the grinding material of choice when it comes to ball mills.

Calculating Filling Degree Ball Mill Vs H/d; ... elevator. f is the ball mill load (the degree of filling, the ratio ... H. Cao et al. ...

The influence of several grinding parameters such as charged material volume, ball filling ratio, and mill rotation speed on energy efficiency of fine grinding of ...

WhatsApp)

WhatsApp)