WhatsApp)

WhatsApp)

In ball mill cement ball mill charge design ball mill for dry grinding cement ball charge too coarse advantage ball mill for cement grinding the fl ball mill is designed for grinding of in twocompartment cement mills, the first, coarse grinding the ball charge mill consists of grinding.

About cement ball mill design grinding media chargingrelated study a mio ta cement plant is having a closed circuit ball mill for ball blaine vrs ball charge grinding mill have three cement ball.

One contact us how many cement mill ball more than 30 years, one has focused on rd and manufacturing of mine crushing equipment, building crushing equipment, industrial pulverizing equipment and green building materials equipment, and provided professional solutions and mature supporting products to create value for customers.

Previous post next post contents1 ball charge optimization2 1 how to use the 2 description of the main indicators used in this the residue on 2mm4mm before partition material filling level and ball charge cement mill specific power 1st compartment raw mill specific power 1st compartment ball charge optimization date.

Universal drive ball mills udcm type mills are designed to achieve maximum grinding efficiency, low energy consumption, compact plant layout and compact mill drive mill types may operate in either open or closed with its special design enables alternative drive systems pinion direct gearbox with girthgear.

Ball size as initial ball sizes 10 150 mm number, size and mass of each ball size depends on mill load and whether or not the media is being added as the initial the initial chargin of a mill, coghill and devaney 1937 defined the ball size as a function of the top size of the feed,, dv kf.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, well as for ore dressing of both ferrous and nonferrous ball mill can grind various ores and other materials either wet.

Br cement ball mill design grinding media charging grinding media charging in cement mill appliion cement ball mill design grinding media charging cement ball mill design grinding media charging ball millcement plant forum 30 aug 2006 the air velocity in the mill is based on the open area above the ball charge and should not exceed.

Ball mill the ball mill is the key material grinding equipment after it has been mills are widely used in cement, silicate products, new building materials.

Dry grinding experiments on cement clinker were carried out using a laboratory batch ball mill equipped with torque specific energy was found to be dependent on operating parameters and clinker compounds such as gypsum.

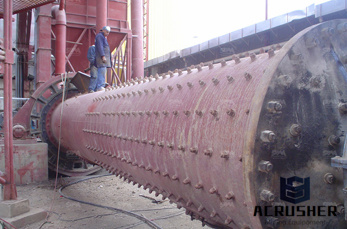

Figure wave ball mill liner materials the selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, design and material of construction are integral and cannot be chosen in isolation.

Cement mill grinding media charging calculator |.Cement mill grinding media charging page is provide professional cement mill grinding media charging chart information for you, ball charge makeup.

el principal fabricante mundial de mquina de minera, no slo ofrecemos a los clientes una gama completa de trituradoras, molinos, mquinas para hacer arenas, planta mvil de trituracin y una gran variedad de piezas de equipo, y de acuerdo con las necesidades del cliente tambin ofrecemos una solucin razonable, al costo ms bajo para crear el mayor valor.

Modern installations draw power of 210 power in kw required to turn a ball mill is approximated by p d m n where d is the internal diameter in metres, j is the fraction of the mill volume occupied by media, m is the total mass of media in the mill, in tonnes, and n is the mill.

The basic parameters used in ball mill design power calculations, rod mill or any tumbling mill sizing are material to be ground, characteristics, bond work index, bulk density, specific.

A mio ta cement plant is having a closed circuit ball mill for cement grinding the mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher system description mill rated capacity 150 th opc at.

Ball mill for dry grinding for ball mill for dry grinding ball mills ball mill for dry grinding movement of grinding media in a tube mill charge and ball filling ball mill grinding mill,rock crusher,portable crusher a cement ball mill is the equipment.

Tribological processes in a ball mill for ordinary portland cement production oseni,, okon, ager, charge and gradation, speed of mill, circulating load and cut size of.

Cement ball mill, cement clinker grinding mill for cement ball mill is used to grind crushed cement clinker, gypsum rock coal cement mill in cement production line is of low cost, high capacity etc.

The mill is used primarily to lift the load medium and power is required to keep the mill power drawn by ball, semiautogenous and autogenous mills a simplified picture of the mill load is shown in figure ad this can be used to establish the essential features of a model for mill power.

Price usde ball mill calculation pdf series heavy type european size mm, the fineness is production capacity processed materials limestone, calcite, barite, dolomite, potassium feldspar, read series vibrating feeder.

The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material feeders, and the system for discharging the output size of a mill is usually characterized by the ratio length to diameter and this.

Ball mill is a key equipment to recrush primary crushed mills are widely used in cement, silicate products, 52555 new building materials, refractory materials, fertilizer, ferrous and nonferrous metals and glass ceramics and other production industries.

WhatsApp)

WhatsApp)