WhatsApp)

WhatsApp)

Capacity of a ball mill 2 production capacity of mill 3 ball mill throughput 4 ballmilling comparing the as.

Capacity to the planetary ball drawing of the operating principle of the planetary ball kinetic model for the trajectory of a single milling ball in a planetary ball mill as shown in, a kinetic model is established in the cartesian.

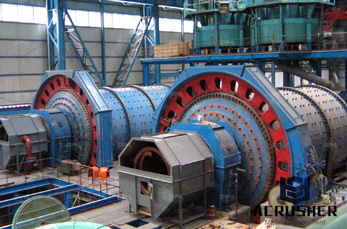

Large capacity mining machine dry gold ball mill brief introduction of ball mill ball mill is mainly used for grinding in mining metallic minerals and nonmetallic minerals, cement, refractories, chemical, power plant, aluminum,building material, glass, ceramic, steel slag and fly ash, ect.

Msksfm13 is a planetary ball mill with four 3 liter alumina jars 12 l capacity the product is extensively used in the fields of geology, mining, metallurgy, electronics, construction material, ceramics, chemical engineering, light industry, medicine, and environmental protection, etc.

Ball mill manufactured by with the most advanced ball mill working principle is widely used in industrial powder cement mill and cement ball mill are highly praised by users at home and abroad.

Application energy saving mining ball mill is a key equipment in beneficiation is widely used in ore dressing production line such as gold ore, cooper ore, magnetite ore, antimony, calcite, kaolin, mica, clay, bentonite etc ferrou metal or nonferrous metal materials.

Ball mill is mainly used for grinding in mining metallic minerals and nonmetallic minerals, cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, follows more crushing and less grinding principle to save feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by revising steel balls ratio.

Capacity size ball mill developed by ftm machinery is priced with other mills of the same quality, our ball mill is greatly are three ways for customers to inquire about the detailed price, that is, by contacting us through the hotline or our online customer service.

Introduction of calcium carbonate ball ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other.

Quality mining ball mill manufacturers exporter buy intermittent mining ball mill small capacity dry grinding ball mill from china manufacturer.

Is lined with mill liners protecting the steel body of the mill and incorporating mill lifters which help to raise the content of the mill to greater heights before it drops and cascades down are three types of grinding media that are commonly used in ball mills steel and other metal balls.

Ball mill grinder,as hammer crusher or cone crusher,is mainly used to grind materials in mineral, cement, refractory, chemical industry, mill has dry and wet wet ball mill works, certain water and other liquid will be added into materials to increase flowability of materials, then the capacity is increased.

Small ball mill, gold ore milling, copper ore ball mill manufacturer supplier in china, offering small capacity gold ore ball mill, copper ore ball mill, top quality gold ore hammer mill, gold ore hammer crusher, low price wet grinding mill for gold ore with model and so on.

Bionics scientific is a leading laboratory ball mill manufacturer in india and offers its customers a fair deal in buying ball mills with facilities of customized size and capacities up to 10 standard, these lab scale ball mill machines come in 2kg, 5kg and 10 kg and are sold all over india at highly competitive machines are supplied with steel grinding balls with different.

Working principle laboratory ball mill consists of cylindrical shell rotating on a horizontal axis mounted on a sturdy mild steel ball mill shell is designed to withstand the rotational load of the mill charged with the grinding medium and the material to be processed..

Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 8 75 hp to 30 x as much as 30,000 ball mills are available with dual pinion or ring motor mills incorporate many of the qualities which have made the marcy name famous since 1913.

Several types of ball mill differ to an extent in their operating also differ in their maximum capacity of the milling vessel, ranging from litres for planetary ball mill, mixer mill or vibration ball mill to several 100 litres for horizontal rolling ball mills.

Small ball mill, gold ore milling, gold ore ball mill manufacturer supplier in china, offering low price small size ball mill, mini ball mill with 501000 kgh capacity, low price wet grinding mill for gold ore with model, high efficiency construction sand washer, double screw sand washer, spiral sand washer and so on.

The ball mill is the most common ore grinding technology today, and probably more than 50 of the total world energy consumption for ore grinding is consumed in ball mills.

Modelling the specific grinding energy and ballmill scaleup ballmill scale up bonds lawdata zbond work index w i zfeed d f and product d size both 80 cumulative passing result the specific grinding energy w mill power draw p wt, where t the mill capacity mill dimensions from tables or charts.

Telephone telephone contact fax well,there is no precise calculation method that can accurately calculate the specific capacity of the cement ball are.

Example mill cylinder total capacity 60 cubic of product to be used for 25 loading 15 is the maximum recommended product loading for dry grinding wet grinding applications the mill may be loaded up to 60 of cylinder total capacity see below.

Energysaving dolomite ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable materials.

Burnt rice husk containing approx 40 50 moisture need to be crushed into powder of size 60 to 80 mesh bss of capacity 2 mt per hr please suggest suitable ball mill with your quotation mentioning p.

WhatsApp)

WhatsApp)