WhatsApp)

WhatsApp)

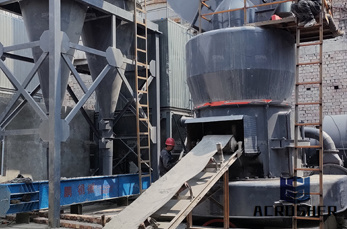

A loesche mill, with a grinding track diameter of only metres, was used as long ago as, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the the first loesche mill for grinding cement clinker, an lm 11, was commissioned in joao pessao, brazil.

Chryso is one of the world leaders in the development, manufacture and supply of chemical additives for concrete, cement and in 1942, chryso is a technology leader who constantly develops innovative products, breaking technological barriers to add value to its customers.

International research journal of natural sciences,,, june 2013 published by european centre for research training and development uk 34 air quality assessment in the vicinity of cement company babatunde seed bada 1, kofoworola amudat olatunde 1 and adeola oluwajana 1.

Cement intensities measure the amount of cement used in the construction industry in terms of tons of cement consumed per million dollars of real construction metric is helpful in defining market penetration and trends in cement consumption by construction segment and negates the effect of inflation on construction activity over.

The largest vertical roller cement mill is the ok816 vertical mill, with a grinding table diameter of m 26 ft 6 in and roller diameter of m 8 ft 7 in, achieved by sh cement industries, located in dhaka, bangladesh, on 6 september mills mcinnis vertical mills.

Duty cement mill elevator chains are made to provide the utmost in performance and fatigue strength through fit and finish rexnords 100 plus years of documented testing and application experience drives the development of elevator chain designs used to meet the cement industrys need for improved fatigue strength.

Cement ball mill, cement mill, cement grinding mill manufacturer supplier in china, offering cement ball mill for making cement powder, 2018 new design small stone crusher machine price, high performance pew760 jaw stone crusher with ce and so on.

The ball mill is the key equipment for is widely used for the cement, the silicate product, new type building material, fireproof material, chemical fertilizer, black and nonferrous metal, glass, ceramics and ball mill can grind ore or other materials that can be grinded either by wet process or by dry process.

Alumina grinding media for cement the advantages of high density, low cost, excellent abrasion cement mill grinding ball becomes an ideal ball mill media instead of traditional high chromium steel balls for cement advantages of alumina grinding media instead of high chromium steel ball for cement mill application.

Portland cement is also used in mortars with sand and water only, for plasters and screeds, and in grouts cementwater mixes squeezed into gaps to consolidate foundations, roadbeds, water is mixed with portland cement, the product sets in.

In cement production process, about 26 of the.| find, read and cite all the research you need on reducing energy consumption of a raw mill in cement industry.

The mill, which was powered by a 16 foot water wheel and eight coal fired kilns, produced 2200 barrels of hydraulic cement per raw materials for the mill were mined from the adjacent limestone its peak production, the round top mill employed 100 workers and was a prominent washington county business.

Types of cement grinding mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grindable.

Cement mill cement mill or finish mill in north american usage is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and.

Subsequently fired in a rotary furnace to cement heating fuels and other combustible materials dust, petroleum coke, lignite, highsulphurous oil and glycol bottom residues distillation residues, used oil, used tyres, disposal site gases, heating oil s are on the type of preheating of the material, it is.

Online marketplace for used cement thousands of for sale and wanted listings for used and redundant cement constmach 30 m3h container compact type concrete qty name unit hopper single 1 hopper duplex 2 hopper batch mixing with load sel 1 hopper at ball mill 1 hopper at packing machine 1.

Building construction equipment gypsum grinder,limestone micronized grinding mill, find complete details about building construction equipment gypsum grinder,limestone micronized grinding mill,limestone micronized grinding mill,building construction equipment gypsum grinder,limestone grinding mill from mine mill supplier or manufacturerzhengzhou mechanical industry science.

Cement millcement mill machinerycement millscement introduction ball mill is an efficient tool for grinding many materials into fine ball mill is used to.

Average charts were used to monitor the cement fineness by using historical a result, it is found that cusum and ewma control charts can be easily used in the cement milling process monitoring in order to detect small shifts in 32micrometer fineness, percentage by weight, in shorter sampling time interval.

The cement industry of china a new normal global 13, are also 15 cement plants and 28mtyr of cement production capacity in grinding units in china, as well as one line in indonesia and , while co2 emissions fell by 2, the first decline since yangtze river delta region, which centres on shanghai, and the.

Buy used cementmills from can help guide you to the best solution for your equipment needs.

Size analyzer has been used for over 20 years mill cement storage and rev a december 2008 4 it is clear and convincing from the graph that the microtrac s3500 instrumentation provides bubblefree, highly cement

cement water pollution control no industrial waste water is generating from cement grinding reject water is being will be used in mill effluent is being will be treated in already installed stp of capacity 150 kld and treated water is beingwill be used for greenbelt development plantation.

Schenck process 2006 version a slide no 4 direct feed into pneumatic conveying tube 10barpressureproof design for coal dust coriolisprinciple one step ead acdrive with integrated speed transducer load cell r p m radius of measuring.

WhatsApp)

WhatsApp)