WhatsApp)

WhatsApp)

Sep 09, 2013· Home Inspection Services in Chicago area. Call us at for a free quote and have a home inspector stop by your future property. The Inspection ...

Discover all the means used to grind your material in a mill on Magotteaux''s website. They are the only supplier offering a wide range of grinding media.

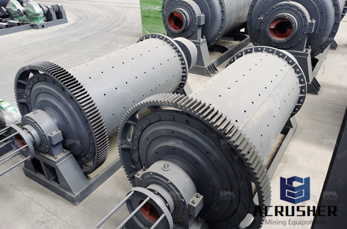

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

End Mill, Drill, and Cutting Tools Manufacturer Melin Tool Company Premium Cobalt HSS and Carbide Endmills, Drills, and Cutting Tools

Sawmilling at WOODWEB''s Knowledge Base. Find articles on metal detector sensitivity and power, sawmill recovery rate, rates for custom milling, portable bandmill ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

Intro: Make a Ball Mill in 5 Minutes. This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or ...

More than 12,000+ ASTM standards are used worldwide to improve product quality, enhance safety and facilitate trade. You can purchase individual standards; a volume ...

Tips for Getting the Best CNC Milling or Turning Surface Finish. CNC Milling Feeds and Speeds Cookbook

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Guhring understands that several manufacturers new to thread milling may need help programming their CNC machines properly.

Bearings SKF is the world leader in the design, development and manufacture of high performance rolling bearings, plain bearings, bearing units and

The Milling Performance Optimizer is designed to provide speed, feed, and metal removal rate values for your operating parameters along ...

Running the correct PROMAX solid carbide end mills at the proper speeds and feeds is critical to obtaining the best production times and tool life.

End Mill, Drill, and Cutting Tools Manufacturer Melin Tool Company Premium Cobalt HSS and Carbide Endmills, Drills, and Cutting Tools

For information on opportunities to reduce sulfur hexafluoride (SF6) emissions from electric power systems, visit https:// ...

Intro: Make a Ball Mill in 5 Minutes. This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or ...

Yet Another Ball Turner for the Lathe. There are lots of designs for ball turning attachments out there so it''s hard to believe that another one is needed.

Economics – Causes And Remedies Of Student''s Poor Performance: A Case Study Of Afikpo North Local Government Area. Economics – Causes And Remedies Of Student ...

LBC, Dseries Next generation of SKF linear ball bearings and units • Increased level of performance • Improved lifetime • Improved reliability and robustness

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

LBC, Dseries Next generation of SKF linear ball bearings and units • Increased level of performance • Improved lifetime • Improved reliability and robustness

Running the correct PROMAX solid carbide end mills at the proper speeds and feeds is critical to obtaining the best production times and tool life.

WhatsApp)

WhatsApp)