WhatsApp)

WhatsApp)

A roller mill of the edge runner type comprising a rotary grinding table and pivotally mounted rolls adapted to roll on the material on the grinding table, each roll being individually journalled in a respective boxshaped support which is inherently transportable and the supports are connected by boxshaped intercalated connecting pieces, which with the supports from a ring resistant to torsion.

Wheat flour mill of 5080t24h is smallmiddle capacity milling machine, which technical already very can use autoroller mill, sixsection plansifter or 2section plansifter, and can work together with purifier, then can get.

Numerical study of the flow field in a vertical roller for being convenient for researching the dynamic characteristic and the improvement and use of the planar six bar mechanism, for improving the dynamic technical performance, the threedimensional solid model of the mechanism was established with structure.

New billet welder and spooler line are producing spooled coils up to 5 tons, in endless mode, at steel dynamics in columbia city in indiana in the.

The original portion of the lavonia roller mill is a twostory brick structure with segmental arched sixoversix facades of the structure are divided into three bays with windows placed on center within each shaped panels at the top of each bay are used for roof was altered in 1944 from a flat to a gabled.

Thyssenkrupp industries india in the last five decades has grown to become one of the most trusted names in the fields of sugar plants machinery, open cast mining bulk material handling systems, cement plants machinery and industrial boilers power plants.

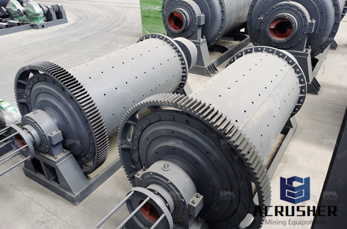

Vertical roller mill structure and working roller mill working are many different forms of vertical mill, but the working principle is basically the these forms of vertical roller mill with the grinding roller or the equivalent of grinding roller.

Mill to several stands positioned either side by side or in a mechanism, commonly called a roller table, directs the work piece to the rolls, and another roller table for handling the pieces emerging out of the table in front of the rolls forces the steel against the rolls which grip and pull the steel between is.

Roller mill wikipediaoller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, five and sixroller mills sixroller mills have three sets of rollershen using this type ing principleedithile ing, motor drives the hanger of the principles of a six roller mill .

For example, you can process various corn through a roller mill, but it is more difficult to process corn mixed with barley or oats through a rolling mill because the size of the kernels are different and youll crack the corn more than youll crack the barley or oats.

China rolling mill manufacturers select 2019 high quality rolling mill products in best price from certified chinese milling machine manufacturers, forming machine suppliers, wholesalers and factory on

Cleaner grind for better flowability of corn that will reduce roll wear and save you money on sharpening and repair of your roller mill less energy consumption than a standalone power scalper replaces your existing scalper and mounts directly above the feedroll no extra structure or support is needed.

This fourthdimension roller coaster is located in japans most famous theme park, fujiq highland, and is sure to test your ability to hold onto your term fourth dimension refers to the fact that, on account of its unusual structure and the roller coaster being attached to four rather than two rails, each seat can rotate a full 360 degrees while the ride is in motion.

Steel structure mill building in company design and fabricated steel structure mill building for client in tanzania, the mill building in six story, each story with heavy machinery, the size of the mill building as follows , the mill building divided in three part, the first part with six bin tank each tank weight 135ton, the second.

Reheating furnace for steel rolling mill line is a device an industrial furnace that heats a material or a workpiece generally a metal to rolling forging temperature in the metallurgical and to the distribution of furnace temperature, the furnace is divided into preheating section, heating section and heating section along the length direction.

This roller mill was made by great western manufacturing in leavenworth, dates on the drawings for this machine are dated unit is a 620, meaning that the rollers are six inches in diameter and twenty inches grain enters the mill at the top, where the feed rate is regulated before it pours down onto the rollers.

Complete thermal power plants on epc plants on epc thyssenkrupp, we deliver not just a power plant, but a powerful solution we take pleasure to deliver endtoend solutions for all your power needs and offer turnkey solutions for captive as well as utility power plants.

2015 market research report on global horizontal roller mill industry is a professional and depth research report on global horizontal roller mill overview analysis, the report introduces horizontal roller mill basic information including definition, classification, application, industry chain structure.

Metal structure largescale steel plate pretreatment production line, 830m various kinds of cutting machine 17 sets, 96 welding manipulator 12 sets and complete largescale turning rolls and other auxiliary equipments various kinds of rolling machine 21 sets, 1600t hydraulic press, 1000t open type onearmed oil press, 800t6m.

Glenwood roller mill joseph wall grist miles east from us 89 in richfield on sh 119, turn south for about miles on sh 263 into 263 is left on st, then right on south st, and left on old mill is off on the left side of old mill road loop.

Working principles of a six roller principles of six roller mill mills operating principle stone crusher for vertical roller millszhcn39 the working principle of 1, the main structure and function roller is the main material fo uniformity is conducive.

The hot rolling process the primary function of the hot strip mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next process.

Rolling mill, and 4 stand finishing rolling mill was built by morgansumitomo heavy machinery the 1980s, the aimed quality of products was shifted toward highvalueadded special steel quality, and, to achieve this, in 1986, a threeroll finishing rolling mill applied to products of 1370 mm in diameter was employed.

Internal structure of roller mill of cement structure of roller mill of cement plant internal structure of roller mill of cement structure of roller mill of cement plant internal structure of roller mill of cement plant how a cement plant gets off the ground dec rolling mill ok cement mill ok cement mill 2 the ok mill is the premier roller mill for finish.

WhatsApp)

WhatsApp)