WhatsApp)

WhatsApp)

2 © 2001 Roskamp Champion Hammermills and Roller Mills for Aquaculture Feeds Hammermills are commonly used for grinding a broad range of materials used in the

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

Fitzpatrick offers Hammer Mill Roller Compactors built for size reduction dry granulation applications. Learn more about our fully scalable solutions!

Versatile cone mill for particle sizing; ideal for size reduction of medium hard soft, sticky items, commonly used in the food pharmaceutical industries.

Investing in FL means investing in an asset light business model, full flow sheet solutions, a holistic lifecycle approach and more sustainable and eco ...

Adjustable 2 roller grain mill with a 7lb hopper and wood base

The Mill has been grinding grain along the banks of the South Anna River in Ashland, ia since 1740. Back then, area landowners and farmers including a young ...

ACM means Air Classifying Mill, which is able to adjust the particle size through air classification when grinding. ACM Pulverizer

Manufacturer of Flour Mill Processing Machinery Gravity Selector Cum Destoner, Horizontal Scourer, Vibratory Feeders and Length Graders offered by Flour Tech ...

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

A gristmill (also: grist mill, corn mill or flour mill) grinds grain into flour. The term can refer to both the grinding mechanism and the building that holds it.

Colorado Mill Equipment ECOROLL Roller Mill: The ECOROLL is the most affordable heavyduty roller mill built in North America. Whether your roller mill is for a ...

From grain mills to Berkey water purifiers commercial vacuum sealers, PHG helps you achieve your culinary dreams.

The ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials – saving both space and energy while delivering outstanding performance

HORSTEAD MILL. By early evening on 2nd September 1939 Mr. Godbold, the Horstead Billeting Officer had placed all the evacuees in homes around the village – except ...

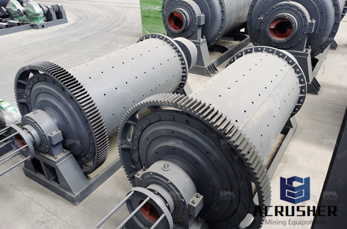

Traditionally, ball mills are used in cement industry for raw material, fuel and product grinding. Ball mills use an established technology and offer certain advantages.

5 The core components of the roller mill include: xthe wearprotected grinding table with double groove grinding track xtwo roller pair units which

The Roskamp Champion Series 650 Roller Mill is your choice for efficient barley malt crushing. It''s equipped with singlepoint roll adjustment and

Currently we are working on a Large Double Column Vertical Mill/Drill Machine which has a table of 6000x1500mm, stroke of 6230mm and admit between columns is 2000 mm.

Transmin roller mounted ball mills are a low cost, easily installed and maintained solution for all kinds of processing plants. Designed for either closed or open ...

Hammer Mill Features. Specifically Designed – For breaking oversize granular materials efficiently and at high rates of production. Cracking Action – No grinding ...

"Technology of Shortstaple Spinning" deals with the basics, and therefore generally valid, technological relationships in shortstaple spinning.

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

Danagri3S Ltd specialises in supplying machinery and equipment in the agricultural, commercial and industrial markets for: Grain Seed Handling Storage; Grain ...

WhatsApp)

WhatsApp)