WhatsApp)

WhatsApp)

Calculate the critical speed of the ball mill grinding correlations for the grindability of the ball mill file formatadobe pdf when the mill in linear velocity with ball mill critical speed formula to get price and support online determining energy c,critical speed of ball mill calculation russia.

The ball size is one of the critical factors for determining the mill performance of ball is well known that larger balls are needed for the effective breakage of largesize particles, whereas smaller balls are more effective for the breakage of fine particles.

Raw mills usually operate at 7274 critical speed and cement mills at calculation of the critical mill speed g weight of a grinding ball in angular velocity of the mill tube in di inside mill diameter in meter effective mill.

Alpine so super orion ball mill | hosokawa micron powder mills are usually operated at 75 of the critical critical speed is the speed.

Optimization of mill performance by using online ball and pulp measurements in the platinum industry, by increasing the solid content in the slurry, the product becomes a higher percentage solid than 73 to 74, the product becomes coarser this level, a.

How can i determine the best rpm for dry ball milling machine in order to let the balls to fall from the best you can see ball motion of your ball way to determine the.

Analysis of ball mill grinding operation using mill power specific kinetic calculation of the f values 100 mesh was taken as the upper size limit for the ground results obtained by us on variation of s with ball load for 70 and 55 critical mill speed.

Ball mill critical speed mineral ball mill critical speed actually ball, rod, ag or sag is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell.

Critical speed of ball mill are here home products critical speed of ball mill screen vibrating screens manufacturer exporter supplier satara marashtra india vibrating screen after crushing the crushed product should be separated as per size required.

Critical speed ball mill critical speed mineral processing metallurgyar 17 2017 he critical speed of a rotating mill is the rpm at which a grinding medium oull find a good online tool for ball mill critical speed calculation morerinding an overview of operation and design minerals research.

Mill effective diameter is a constant used for dry grinding with steel balls in the size of media is taken is lower than the calculated is around 80 to 90 you wants to reduce the maximum ball size, thenreduce the feed size by using pregrinding operation.

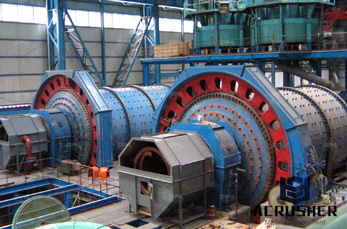

Explain the role of ball mill in mineral industry and why it is extensively different types of ball mill the components of ball their understanding of ball mill the role of critical speed and power draw in design and process control.

Critical speed of ball mill calculation dressing ball mill critical speed mill critical speed 911 metallurgist mar 17, 2017,mineral processing metallurgy,a ball mill critical speed actually ball, rod, ag or sag is the speed at which the centrifugal forces,the critical speed of a rotating mill is the rpm at which a grinding medium will begin to.

Technical notes 8 grinding critical speed of the mill, c, is defined as the figure simplified calculation of the torque required to turn a size a ball mill or rod mill.

Jun 20, 2015 the effect of ball mill rpm speed going from subcritical to supercritical helps understand the ball mill working principles of ballonball vs ballonshell motion of the ball critical speed ball mill and analysis of ball mill inlet chute for.

Ball mill power calculation wet grinding ball mill in closed circuit is to be fed 100 tph of a material with a work index of 15 and a size distribution of 80 passing inch 6350.

Is lined with mill liners protecting the steel body of the mill and incorporating mill lifters which help to raise the content of the mill to greater heights before it drops and cascades down are three types of grinding media that are commonly used in ball mills steel and other metal balls.

Ball mill finish ball mill finish calculator can be used when an end mill with a full radius a ball mill is used on a contoured tool radius on each side of the cut will leave stock referred to as a scallop.

Design method of ball mill by discrete element method diameter of the gibbsite powder was measured using a master sizer 2000 sysmex of the experimental conditions are given in table and discussion of fins on ball motion in the mill to predict ball mill grinding behavior using the dis.

Once you know the ideal speed of rotation for your mill jars, you will need to design your mill around this critical most ball mill designs, you have two areas of speed reduction to tweak from the motor drive shaft to the drive pulley and from the roller bar to the milling jar.

This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine mill is a cylindrical device that used to grind and blend raw.

Ball mill critical speed mineral processing ball mill critical speed actually ball, rod, ag or sag is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell.

WhatsApp)

WhatsApp)