WhatsApp)

WhatsApp)

Rod mills are very similar to ball mills, except they use long rods for grinding media. The rods grind the ore by tumbling within the the mill, similar to the ...

Automated Adjustment of Rod Mill Grinding based on the Frequency Analysis of Acoustic Emission P. Tynia, R. Heikkiläa, I. Hynynenb M. Paavolab

Rod mills are mainly used for primary grinding of crushed ore with a particle size range up to 50 mm for soft materials, and between 20 and 30 mm for harder materials ...

a rod mill ball mill circuit where new feed to the rod mill is 250 mph solids both mill discharges join together at cyclone feed. Full text of "The mechanical ...

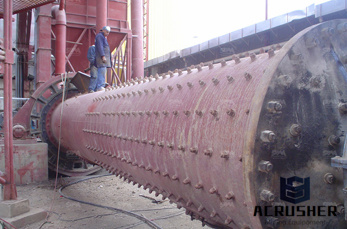

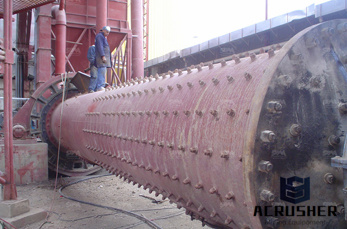

The rod mill, a tumbling mill characterized by the use of rods as grinding media, is used for grinding ores, coal/coke, and other materials for both wet and dry applications.

Metallurgical Rod Mill Capacity and Sizing ROD MILL ROD MILL ROD MILL General PERIPHERAL ...

1. Rod Mill and Ball Mill. Rod mills are grinding machine which employ high carbon steel or special steel rods of nearly the same length as that of the drum, in place ...

Oct 24, 2009· Rolling of billets to wire rods. This is a video showing how a billet is converted into a wire rod. A billet is .

Oct 24, 2009· Video embedded· Rolling of billets to wire rods. This is a video showing how a billet is converted into a wire rod. A billet is heated to austenetizing temperature .

Know the subtle but important differences between ball mills and rod mills when selecting used grinding equipment for your mining site project.

we are manufacturer of Cast Iron Chilled Rolls (Mill Rolls) for the Bar Rod Mills, roller flour mills, steel rerolling mills other various milling industries.

It is a page of the detail of Bar and Wire Rod Mill of Steel, manufacturing, installation, sales and aftersales servicing of steelmaking machinery ...

Wire Rod Mill Prakash Industries Limited. Towards forward integration of the processes, company has set up Wire Rod manufacturing Wire Drawing facilities (HB Wire ...

Rod mills are less common than ball mills for grinding minerals. The rods used in the mill, usually a highcarbon steel, can vary in both the length and the diameter.

A rod mill is a piece of mining equipment that manufacturers use to break down material for processing. While these machines are not as common as their mill counterparts, the are still widely used in North America.

Rod mill is a type of grinding mill whose grinding media is steel bar, while ball mill is steel ball. 1. Rod mill are usually applied to grinding the wsn ore and rare metal in the .

The rod mill, a tumbling mill characterized by the. use of rods as grinding media, grinds ores, coal/. coke, and other materials for both wet and dry p a. plications. The rod mill accepts feed ore as coarse as 1 1/2".

Rod mills are very similar to ball mills, except they use long rods for grinding media. The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill. To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at to

Table of ContentsLinear Nonlinear Grinding ModelsExperimental MethodsBatch Mill ExperimentsContinuous Mill ExperimentsMaterial Breakage Kinetics in a Rod MillThe ...

The invention relates to a method for determining the rod diameter of a rod mill, belonging to the field of ore grinding and levigating technology. The method ...

Metalworking. a mill for making metal rods. 2. a mill for grinding ore or the like by means of steel rods. Origin of rod mill. .

Rod mill is also called rod grinding rod mill, bar mill and rod grinding mill. Our rod grinder is especially suitable for crushing river gravel to make sand. It''s a kind of effective and energy saving rod grinding machine.

Application : Cement Plant, Clinker Grinding Unit, Steel Mill, Mining Capacity : t/h Motor Power : 751400 kW Fineness : mm

rod mill [′räd ‚mil] (mechanical engineering) A pulverizer operated by the impact of heavy metal rods. (metallurgy) A mill for making metal rods.

WhatsApp)

WhatsApp)