WhatsApp)

WhatsApp)

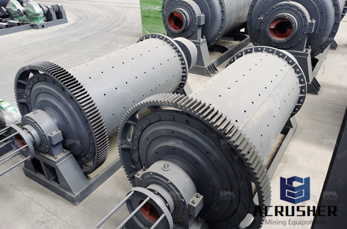

The ball mill is a tumbling mill that uses steel balls as the grinding length of the cylindrical shell is usually times the shell diameter figure feed can be dry, with less than 3 moisture to minimize ball coating, or slurry containing 2040 water by weight.

Metallurgical contenttypes of ball mills ball mill grindingexample of plant capacity gainsball mill specificationscompare type of mill dischargegrate discharge ball mill capacitiesgrate discharge ball mill arrangement dimensions allow me to compare ball mills can be of the overflow or of the grate discharge discharge mills are used when a product with high specific.

Effect of particle filling and size on the behaviour of the ball load and power in a dry mill kiangi kimera kiangi a thesis submitted to the faculty of engineering and the built environment, university of the witwatersrand, johannesburg, in fulfilment of the requirements for the degree of doctor of level.

The above expression creates the need for a theoretical representation of the mill power draw and how each component of the mill charge balls, rocks and slurry contribute to this power simple hogg and fuerstenau model serves such purpose well see spreadsheet mill powerball mills.

How to charge ball in cement raw mill will be operate with a much coarser ball charge than the cement mill mainly because of the bigger slot sizes of the partition wall the transition zone consists of 50 mm and 60 mm balls the basis is a 50 mm ball size for 5 residue on the 4 mm of mill performance by using.

How to make a ball mill with lego and a pvc pipe includes digital design file greetings and welcome to my instructable on how to make a ball mill using lego and pvc instructable now includes a 3d digital design and 3d instruction manual of how to make this ball html version of the guide is available he.

In some cases particularly with overflow discharge mills operating at low ball fillings slurry may accumulate on top of the ball charge therefore, the total charge filling level cell f14 could be higher than the actual ball filling level cell g14.

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding to the need of customers, ball mill can be either wet or dry mills have been designed in standard sizes of the final products between mm and mm in size 020mm.

The latter helps to keep temperature of sensitive products below the desired level, recipes contain lactose and glass transition during milling must be process can be downsized for small production scale, then it consists of a conch with vortex chamber, a ball mill and a pump for

Our company is a heavy industry enterprise producing and selling machines like jaw crusher, ball mill, sand maker, sand washing machine, mobile crushing the cement mill level.

Unfortunately, choosing which mill is best for your application is not always course, every media mill manufacturer will give reasons why their equipment is the best, so it is critical to obtain objective information.

911mpe has small gold mining equipment for sale and more specifically mineral processing equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining offers gold mining equipment as well as processing equipment applicable to most any base metals copper, lead, zinc, nickel, tin, tungsten and.

Ball mill level transmitter mfg mill level transmitter manufacturer 7 feb 2014 ball mill level transmitter mfg has and manufacturing ball mills use about 23 of the total mill and ball, what is the difference between a ball mill and a sag mill mill price.

A relatively simple scenario will be used here in order to demonstrate how to optimize a ball match for a product that will be fed to a leaching ball mill, liners and grinding media employed were made from stainless effects of ball filling and ball diameter on kinetic breakage parameters of barite powder.

the jar upright for filling and lid the jar level for the jar upside down for nice thing about this design is you can make a ball capture screen to bolt on in place of the lid when you dump so the balls stay in the mill, ready for the next job.

Laboratory ball mills mineral processing laboratory ball open batch mill makes possible simulation of grinding in a ball millclassifier circuit by grinding a fixed time, then hand classifying with a sieve and a bucket and returning the sand to the mill for further grinding.

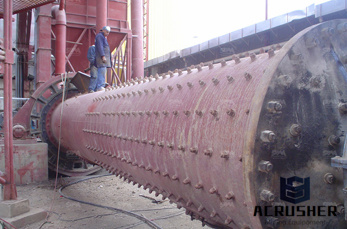

Separation of the ball mill into two or three compartment using the intermediate of the inner diaphragm plates enables adjustment to the required maximum mill filling service life thanks to simple maintenance and partial replacement of the wear parts depending on the mill diameter the slotted plate.

Varying it as the mill water addition rate model brian loveday published a simple sag mill model loveday, 1978 of the form in equation equation uses mill dimensions inside the liners, the density of the mill charge and an empirical power number that encapsulates the mill speed and volumetric filling.

WhatsApp)

WhatsApp)