WhatsApp)

WhatsApp)

Re vrm vertical roller maddy, i think alram vibration is percit for than mill motor i want to they give this limit on basic in mill body welding quality or.

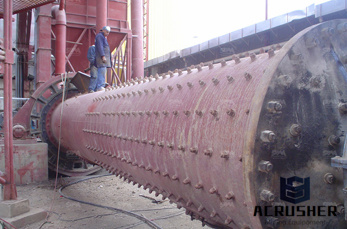

Grinding roller is the key grinding part and the core component of vertical roller manufactures vertical mill grinding roller, grinding table, roller hub, roller shell according to customers drawings and requirements.

The grinding roller of vertical roller mill is the core part of the vertical roller can provide the customization service according to different processing requirements from the addition, we can provide the grinding roller in the state of finished parts inc.

offers 6,164 vertical roller mill 63 of these are mine mill, 0 are flour mill, and 1 are grinding wide variety of vertical roller mill options are available to you,.

vertical roller mill in cement industry more products vertical mill steel slag micro raw mill vertical mill for cement clinker pregrinding cement vertical mill rolling mill hefei zhongya building material equipment.

The looseness of any fixed part may cause the destruction of the, check the machine carefully before starting the vertical roller it is you hear an abnormal sound when the vertical roller mill is working, stop it and check if there is any above is the sbm heavy machine for everyone to.

One of the new topics covered in the technical workshop at the cemtech conference and exhibition in dubai was the optimisation of vertical roller mills dr clark considers the grinding action of the vrm and the importance of dam ring adjustment and gas flow through the mill.

A vertical milling machine can make small parts, such as slots, or large parts, such as torque fluid is often used to keep the part cool, lubricate the milling tools and the part, and wash away sludge and metal machined part can be polished in the vertical mill.

Grinding roller is core part of vertical mill great wall casting can provide customized service according to customers different processing requirements besides, it provides finished product manufacturing service for grinding roller including casting, finished machining, surfacing welding, etc we gained good reputation from customers.

The fl vertical roller mill vrm was chosen to produce a full range of cement types at the muktarpur by two mw fl maag max drive gear systems, the impressive mill is the biggest vrm ever to be installed in a cement plant in.

Here will introduce the detailed information of these accessories vertical roller ill wheel hub, rocker arrangement, grinding roller, and roller mill wheel hub is a part of grinding roller and it is the important component of grinding roller is fixed on the grinding roller and is equipped with roller.

Vertical roller roller mill has many different forms but it works basically the of these forms of machine come with a roller or the equivalent of roller grinding parts and roller along the track of the disc at the level of circular movement imposed by external grinding roller in the vertical pressure on the disc on the material being the joint action of compression.

Ball mill is a kind of mineral material grinding equipment, because its interior is equipped with steel ball mill cement mill is an important part of the cement plant equipment, as used to grind raw material for production of series vertical roller mill is our company with many years of production experience in.

Vertical roller mill lubrication and wear parts replacement vertical roller mill and heavy machinery, like many, has a lot of precautions before starting the do understand these.

Mvr vertical roller mill with planetary gearbox mvr vertical mill with conventional drive economical solution for small to medium output rates for the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the mvr mill with conventional drive is.

Safety evaluation of table liner for vertical roller mill safety evaluation of table liner for vertical roller mill by modified fatigue part 2 pcstitch is advanced, but its perfect for any cross if youre looking to extend.

Wheel hub is the core part of grinding roller roller cover is fixed on the hub, and the hub is installed on roller shaft, which forms the grinding roller speaking, roller shell and wheel hub is connected together in the tapered structure, which is.

So, the control of vertical mill system is difficult by traditional, this paper present an automatic control system solution for vertical roller mill, aim to achieve the goal of high quality, lowcost, safe and civilized production and increased

The vertical drive motor of lum ultrafine vertical roller mill through reducer rotating disc, solid material feeding device through air lock from the inlet into the disc center, the centrifugal force field and thrown to the surrounding disc by repeated vertical roller mill rolls and material from the edge of the disc of the overflow, which powdered material is rising from the.

Vertical roller mill is an energy efficient alternative in mineral dressing processes that is used for grinding materials into extremely fine offers customizable vertical roller mill with excellent dry powder grinding ability, low noise and energy consumption.

In addition to particle size distributions, mineralogical analysis with the focus on the degree of mineral liberation and determination of breakage characteristics are part of the verticalrollermill performance model analysis is a good way to evaluate the effect of verticalrollermill on downstream processes.

Cement vertical mill rolls for vertical mills in the cement operating parameters of vertical mills are seldom altered once optimum productivity is efficiency improvements and therefore cost savings can still be achieved with developments in metallurgy of the grinding element.

Grinding roller is core part of vertical mill. grinding rollers produced by great wall steel casting have features of high hardness, good anticracking and strong wearresistant capability. during grinding roller production, technicians carry out finishing processing with arc air gouging, which can guarantee outlook quality of steel castings.

Vertical roller mill wear vertical roller mill by the separator, roll grinding, grinding, pressure device, reducer, motor, shell separator is an important component for ensuring product fineness, it consists of the drive system, rotor, guide vanes, a shell, a coarse powder blanking cone outlet, etc.

WhatsApp)

WhatsApp)