WhatsApp)

WhatsApp)

standard ball mill specification mayukhportfolio. standard ball mill specification. Grinding process test plant capabilities . Screen analysis of as received ...

calculation for speed of ball mill of 21 rpm – . Ball mil design calculation? – Yoo! Answers. Apr 01, 2008 · Ball mil design calculation? .

What it is the optimun speed for a ball mill ? posted in Pyrotechnics: I have done a ball mill, recenly finished, but the motor has too rpms, is too fast for use ...

ball end mills dynamic sfpm/ipm cnczone the largest . milling question: i think i understand pretty well how to calculate rpm a ball end mill would require different ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Three Roll Mill Lab Model. LLC is a low cost leader in the manufacturing of mixing equipment such as three roll mills and planetary ball mill is the ideal tool in RPM.

COBALT HSS AND HSS END MILLS Speed and Feed Data Applications in Various Materials ... RPM PER TOOTH 1/ .005 .

End Mill, Drill, and Cutting Tools ... End Mill Training Speed and Feed Calculations. ... Revolutions Per Minute (RPM) The spindle speed rate of the cutter.

Ball Milling Equipment Porcelain Jars Internal Capacity PTA01 Model Ball Mill Wheel Attachment Fits on the VLWhisper or RKWhisper with a 12" wheelhead

what if grinding mill rpm ... mill running at 8 rpm low solids percentage may also increase the standard. ... ball mill rpm calculation introduction ...

Paul O Abbé Equipment Company is a manufacturer New Steel Ball Mills and Milling Equipment. Call or request a quote to get started.

TYPE OF MILL MEDIA SIZE RPM TIP SPEED (fpm) Ball Mill 1/2" and larger ... The critical speed of a ball mill is calculated as divided by the square root of ...

Quick Easy Black Powder Ball Mill ... Standard length mill times are half an hour for individual chemicals, ... Optimizing the Ball Mill''s RPM

In a ball mill of diameter 2000 mm, 100 mm dia steel balls are being used for grinding. Presently, for the material being ground, the mill is run at 15 rpm.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Jar Mills, Long Roll Jar Mills, Grinding Mill Jars, Grinding Media and Drum Rollers

Ball mill rpm calculation on size – Ball mill rpm calculation on size. Gulin supply Mining and construction equipment for mineral handling.

Planetary Ball Mills RETSCH''s innovative Planetary Ball Mills meet and exceed all requirements for fast and reproducible grinding down to the

Standard Reach Ball. ... .005 Ball End Mill Here is a 1/8 x 11/2" solid carbide ball end mill with a .005 ... 4 Flute Square Standard; 4 Flute Ball Standard; 1/4 ...

Building a Ball Mill By Jeff Thorsgaard, Thorsgaard_foundry Building the Machine. I built a ball mill from looking at a picture of one on the internet.

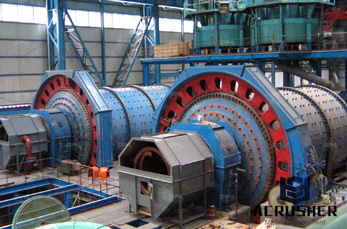

Lipu ball mill is used to grind cement, silicate product, new building materials, refractory materials, chemical fertilizer, ferrous and nonferrous metals, glass ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

standard rpm of a ball mill; 9x20 Lathe Ball Turners Knurlers MicroMachineShop. 9x20 Lathe Ball Turners Knurlers Last updated on Friday, July 29, 2016 06:01 ...

Comparison of Planetary Ball Mills ... an initial comparison was made at the maximum speed achievable by each mill." PM100 p6 Maximum Speed 550 rpm 550 rpm

WhatsApp)

WhatsApp)