WhatsApp)

WhatsApp)

The two roller units remaining in the mill then continue the grinding mill system from polysius thus fulfils the prerequisites for online operation in the cement factory with a practically uninterrupted flow of material from the mill to the kiln.

Process area incharge clinkering northern punjab rawalpindi, pakistan 138.

Correct timing on the maintenance of a first chamber cement mill lining and the successful implementation of an expert system on a cement mill both offer benefits in terms of power consumption see case studies process measurements are also key to energy saving compressors are another area for attention.

Hormigones transex ltda., santiagochile, awarded the order for a lm 46 22cs cement mill in puente alto in chile to loesche automation was charged with providing the electronic and automation engineering for this mill.

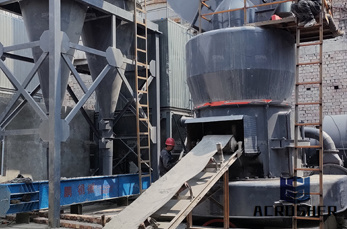

Cement making plant we use in this whole production line are vibrating feeder, jaw crusher, impact crusher, cement ball mill lifer, preheating system, cement rotary kiln and packing machine and so the cement equipment in this line can be provided by our factory.

Buy ball mill rubber liner promotions, sales rubber liner of cement mill rubber mill liners are chosen for most primary, secondary and tertiary ball in many cases rubber components are best suited for specific areas in rubber liner for ball mill and sag mill liners have a predictable wear rate so.

In the 19th century roller mills were adapted to grist mills before replacing mill used either steel or porcelain the years 1865 and 1872, the hungarian milling industry upgraded and expanded the use of stone mills combined with roller mills in a process known as hungarian high milling.

In the traditional cement factory, it is impossible to estimate cement strength with any certainty until its 1day and 28day strengths are measured through physical tend to compensate by using costly, highquality limestone and additives to ensure a highperforming, they may mill the product.

Study of a cogeneration plant in sugar mill by using bagasse as a is a more potential in a cement factory for electric power generation using waste heat recovery compared to the.

Cement industry has been always among the largest co 2 emission 57 of global co 2 emissions are caused by cement plants, while 900 kg co 2 is emitted to the atmosphere for producing one ton of this work, global strategies and potentials toward mitigation of co 2 emissions in cement plant have been discussed and the most promising approaches have been introduced.

Cement powder, here conditioned in bag, is mixed with fine and coarse aggregates and cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them is seldom used on its own, but rather to bind sand and gravel aggregate mixed with fine aggregate.

Because of the lower emission limits in force, cement kilns and a growing number of other processes are replacing electrostatic precipitators with high temperature bagfilters to abate emissions, which are exposed to elevated environmental stresses and therefore are more prone to failure.

Indarung 4 cement mill use of ball mill in cement plant ccr means in cement factory crusher stacker reclaimer of working in india cements cement mill operation semen padang company case study pt semen padang company case study the kiln and cement mill in the indarung ii plant, replacing the airlift by a mechanical.

Raw amp cement mill operator rampc operator mtw series heavy type european grinding output size mm, the fineness is production capacity processed materials limestone, calcite, barite, dolomite, potassium feldspar,.

Replacing esp with bag main esp in our new line 5000 tpd is running with very low efficiency especially when the raw mill be supplier tried to modify it but he failed plant stopped 21 days now they want to replace it with bag filter.

Platin cement works has reached its present state of development in three main initial decision taken in the late sixties to build a new factory some two miles southwest of drogheda, where cement had been manufactured since 1938, culminated in the completion of a 400,000 tonnes capacity single kiln unit in 1972.

Possibilities and effects of using waste materials as energy in cement december 25, ciments dobourg in belgium cut out fuel expenses, replacing 8090 of fuel with have been similar experiences with facilities in italy ambiente, which fully adapted the cement factory in ravenna to use waste as.

Cost of ball mill, ball mill for sale, ball mill introduction as an efficient machine for powder grinding, zeniths ball mill is widely used in powder making production line including cement, new chat now.

Optimization of cement grinding operation in ball mills several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses typically in combination with a ball mill, and clinker pregrinders with.

In fact, replacing humans is often entirely the thus it was worth it to millowners to invest in a machine that would allow them to reduce the number of workers needed to make yarn.

The end customer is the egyptian cement for cement projects management planned new plant is located nearly 500 km south of cairo in loesche scope of delivery includes a raw material mill with a capacity of 540 th of cement raw meal, a cement mill with an output of 350 th of clinker as well as a coal mill with an output.

In this study, the first and second law analysis of a raw mill is performed and certain measures are implemented in an existing raw mill in a cement factory in order to reduce the amount of energy.

WhatsApp)

WhatsApp)