WhatsApp)

WhatsApp)

Do roller mills produce a more uniform grind compared to flat burr grinders i havent found all that much information on how the two compare, but im wondering if a roller mill type grinder would have a narrower particle distribution curve, and hence produce a better know that roller mills for grinding coffee have primarily been large, expensive, industrial machines.

The mcdonald mill has changed all taking a chance that a small mill would work, and putting considerable research time into it, hugh mcdonald has proved it he has provided us with detailed plans about how to build this wonderful machine.

Because i wanted to buy grain in bulk, but didnt want to pay 100 or more for a prebuilt grain mill, i decided to make my is a diy mill, and a cheap one at that, so does have its drawbacks namely time to got about 68 efficiency from this, whereas with my setup and commercially crushed grain i usually got 70.

Make sure you keep your grain mill dry at all times so the rollers wont develop rust and become difficult to to mention, rust could flake off into your grain, and make its way into your of moisture, remember humidity in the air can also cause rust to form on metal.

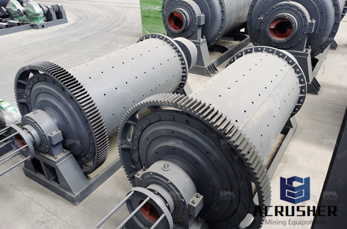

These machines function similar to a steam roller, and pulverize items into smaller particles or mill machines are widely used in the agricultural and foodprocessing industries, particularly in grinding grains and barley to make bread, flour, and machines may also be used to grind rocks during mining operations, or.

Moreover, the market is served by customer concerned metal straightening machine suppliers, who ensure the year round stock of the products to meet the short notice requirement of the following listings for your any requirements for metal straightening machines for straightening any kinds of metal products.

First, the removal and repair methods grinding roller device roller sleeve and the roller bearing on the ball mill wear parts, generally when the roller device is a problem is that these two parts of the problem, they just need to split out maintenance on it.

Roller size the roller size will vary depending on your intended purpose for using the type of roller should you get a combination roller is typically used more to make halfround roller is also appropriate for this rollers are typically used for more generalized metal processing as well as sheet metal.

When sheet metal is inserted between two such rolls, the urethane wraps the sheet metal tightly against the steel roll similar to a radius forming urethane press brake die, and since the urethane roller is driven, the sheet metal is roll formed into a precise radius.

22 inch two roller mill open mixing mill, find complete details about 22 inch two roller mill open mixing mill,open mixing mill,two roller mill,two roller mixing mill from rubber tworoll mills supplier or manufacturerqingdao eenor sciencetechnology co., ltd.

Guide for rolling mill good price hot rolling rolling mills for wire shear for metal machine for steel turret for steel roller induction melting rolling mills for wire roller.

Buy a mini rolling mill to conserve space and carry out precision metal work such as our small durston rolling mills, with rollers ranging from 80mm to also stock combination mills and heavyduty mills capable of rolling metal up to 130mm wide and 7mm thick.

If you are going to make a larger grain mill, then it may also be a good idea to make the hopper in such a way that it will act as a cover for the internal mechanism when not in last thing you will want to do is invest in building a larger grain mill with metal rollers only to have the rollers develop rust or some other form of corrosion.

Page 1 of 4 shaping metal without milling or using lathe posted in atm, optics and diy forum i would absolutley love to own a metal lathe or a milling machine, or even a cnc machine but i sre as heck dont have the money for either of those at the moment so i am wondering if any of you have had this problem and came up with a nice solution to cutting and shaping certain metals like.

Making a metal roller sign in to follow a metal you want to reduce the thickness of hot steel by rolling or do you want to make circles and rings from hot or cold metalboth are called rollers though the first one is better called a rolling share this to post share on other sites.

The roller mills increased the amount of flour as well as speed up the milling mills could produce more marketable flour than millstone ground first gear driven roller mills used in washburn a mill, minneapolis, mills used more belt pulley drives with metal shafting and less large gears.

Grinding roller is core part of vertical metal casting can provide customized service according to customersdifferent processing, it provides finished product manufacturing service for grinding roller including casting, finished machining, surfacing welding, gained good reputation from customers.

Other roller mill designs home roller mill makers have been known to were nice enough to feed my thirst for knowledge, here in short are there yep, this is the guy from engineered a 2 roller mill that will handle motor driven it has 2 unknurled 6 diam.

I originally planned to make a cement roller mill but this investigation is being tackled by others see box on previous dimensions the question of roller dimension and texturing is very important to the design and success of a know a 1in.diameter roller with a medium knurl works well on a homebrew mill.

Jewelers use rolling mills for shaping metals, fabricate jewelry by hand or making models of your is easier and faster to make your own sheet and has international rolling mills collection for sale.

The thickness of the material layer is related to the feed quantity and the adjustment value of the discroller in order to keep the roller from contacting with the grinding disc, reduce the wear and vibration between the metals, and make the metalsilicon mill start under noload, there should also be a gap adjustment device.

One wire roller use to form wires into a d shape or v shape cross rolling mill texture forget to experiment with more textures and objects that could be embossed into your sheet a closer look at how each roller works and for more inspiration, watch our video with dave wilson texturising below.

Turning down roller shafts i left the major diameter alone, since it is crs, it will be close enough for sheet metal chucked up the roller in a 4 jaw and dialed put a steady close to the chuck and slid it down to the other again with dial indicator.

The williams roller mills are designed to provide years of reliable, consistent, and efficient operation, but the reason why williams is one of the leading roller mill manufacturers is their ease of use and more about the features of the williams roller mill.

WhatsApp)

WhatsApp)