WhatsApp)

WhatsApp)

What Is Ball Mill And Its Working Principle? The usage of ball mill and its technical data Ball mill is widely used for grinding ores and rocks in metal and nonmetal ...

Ball Mill Operation and Maintenance Source: clirik By Ammy Posted: . Ball mill has features of high operation rate, grinding effect, and we must follow ...

Ball mill operation and maintenance. To make the ball mill operate good, we must strictly abide by the operation and maintenance procedures. Before starting the ball ...

used ball mill for sale,ball mill design in india,south africa. Ball Mill operation. The materials will be crushed and mixture by the impact effect of falling ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » Several energy efficient options for cement grinding are available today such as vertical ...

1 YANACOCHA GOLD SINGLE STAGE SAG MILL DESIGN, OPERATION, AND OPTIMIZATION Ben Burger 1, Luis Vargas, Hamer Arevalo, Sergio Vicuna1, Jim Seidel2,

· ... Raymond Mill; Ball Mill; Mtm Ball mill full operation cement mill roller operation . vertical roller mill for sale ? The New Blog Peoria Project.

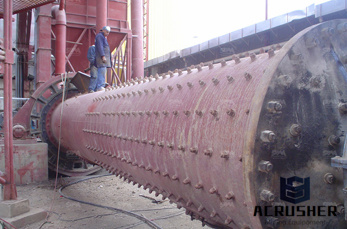

A ball mill is a grinding device that is used to turn material into fine powder. Ball mills are cylindrical in shape, and are often the grinder of choice when it ...

COPPER MOUNTAIN: OVERVIEW ON THE GRINDING MILLS AND ... which just has started commercial operation earlier this ... Each Ball mill is also driven by two 8,500 ...

ball mill in full operation. Home / Products / ball mill in full operation; Lab ball mills,Lab Powder Equipment,Lab Glove Box, Operation Box .

Paul O Abbé Equipment Company is a manufacturer New Steel Ball Mills and Milling Equipment. Call or request a quote to get started.

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

Dry grinding is more often a continuous operation and is more ... the shell interior for a full revolution of the mill. ... of a ball mill is calculated as ...

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary significantly ... • slurry density in case of wet grinding operation.

· RecrystallizedRocket. Loading ... Ball Mill Critical Speed Working Principle Duration: 5:40. 911 Metallurgy Corp. 78,358 views. 5:40.

Ball mill operation is anything but simple. In ball mills using dry solids, the primary independent variables include mill speed, mill diameter, media size, residence ...

ball mill for a particular operation [17]. The various ... Surfactantassisted ball milling: a novel route to novel materials with controlled nanostructure ...

Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints ...

Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft. x 8 ... In the discharge end of this mill, a slotted full ...

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

Ball Mill Grinding Capacity Calculator Ball Mill Motor/Power Sizing Calculation ... Ball Mill Design/Power Calculation. ... Here is a section of a mill in operation.

WhatsApp)

WhatsApp)