WhatsApp)

WhatsApp)

Aug 14, 2010· Well!!! Advantages of down cut milling: * Better Surface Finish: The gradual decrease in cutting force and absence of sliding and crushing usually results ...

2 Tools for Optimizing CNC Milling Cut ... heat can build up ... You''re profiling a wall and you''d like to do it in a single pass instead of having to step down ...

USING CARBIDE INSERTED TIP TOOLS Sherline Products. The obvious difference between carbide tools and inserted . can speed up the cutting process. .

When choosing a method to machine, up cutting or down cut milling (climb milling) is decided by the conditions of the machine tool, the milling cutter and the ...

Best used for Standard milling dadoing and boring Cutting Diameter 1/4 Cutting Height 3/4 Shank Diameter 1/4 Overall Length 21/2 Flutes 2Upcut endmills direct ...

Stability charts and chatter frequencies are determined for partial immersion up and downmilling, ... respectively, the nominal depth of cut b, ...

Upcut, downcut and compression cut determine the way the chips (cut material) are ejected and the smoothness of the surface. With an upcut end mill, ...

Difference between up and down milling machine? ... What is the difference between up and down? ... ary tool bit to cut and shape the work piece.

China Up And Down Milling Cutter, Up And Down Milling Cutter from China Supplier Find Variety Up And Down Milling Cutter from laser cutter,brush cutter,pizza ...

There are two distinct ways to cut materials when milling, conventional (up) milling and climb ... workpiece down, ... CONVENTIONAL MILLING VS. CLIMB MILLING NUT

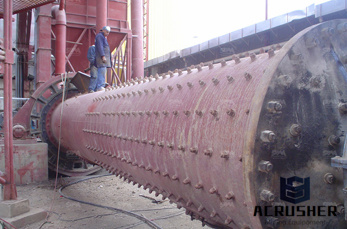

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

Choosing Your Milling Bit End mills, also called milling bits, are the most commonlyused bits used with CNC machines. ... UpCut, DownCut, ...

2 Q2. (a) Differentiate between downcut and upcut milling in detail and list the advantages and disadvantages of both while using peripheral cutters.

Speed up your milling with constant cutter forces ... Then repositions for the next cut. This allows milling at an efficient rate ... but rather stay down as it ...

Metal Cutting Processes 2 Milling : ... In up cut milling, ... Down Cut Milling. In down cut milling, the cutter rotates in the ...

Nov 01, 2014· Working of engineering things electrical things Working of engineering things electrical things So comment, like and subscribe Thank you!!!!! Your We...

Milling Bit suggestion for Quiet Cut Spindle with ER11. ... UpCut, DownCut, ... The cutting style of a milling bit identifies which way the material chips are ...

Which method to be used will depend on the machine and the face mill cutter that has been selected. Generally down cut machining offers longer tool life than up cut ...

Check out our frequently asked questions page. ... How much will it cost me to have my log cut up? ... I have a tree that needs to be cut down. Can you do it?

CNC Milling: Introduction to cutting tools . ... In end milling, ... End mills are intended to cut horizontally. Upcut, downcut and compression cut determine the ...

Technical Support Page CONVENTIONAL VS CLIMB MILLING ... "UP" MILLING CLIMB – "DOWN" MILLING ... • Tooth meets workpiece at top of cut.

Spiral solid carbide router bits by Amana feature outstanding tool longevity, ... Solid Carbide Spiral Finisher UpCut DownCut 3 Flute Router Bits.

Solid Carbide Spiral, Cutting UpCut and Down ... Specifically designed for milling ... Choose Your Solid Carbide Spiral, Cutting UpCut and DownCut ...

Upcut milling, downcut milling A Upcut milling B Downcut milling C optimum feed direction for straight grooving D optimum feed direction for laminate

WhatsApp)

WhatsApp)