WhatsApp)

WhatsApp)

Particle Size Distribution of Different Grinding Systems Free download as PDF File (.pdf), Text File (.txt) or read online for free. Particle size distributions for ...

Choosing the Right Laboratory Ball Mills; Conventional Ball Mill vs ... Union Process manufactures a broad line of particle size reduction equipment such as wet ...

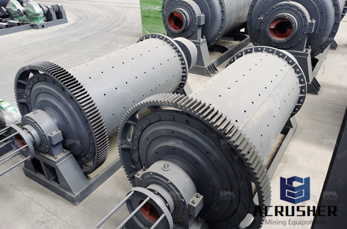

Our combined experience in ball mill design and process ... Particle size reduction of materials in a ball mill with the presence of ... Steel Ball Mills.

Ball Mills are used for the particle size reduction of a wide variety of materials. In a range of sizes and often used in high volume applications.

Laboratory Ball mills and ring mills and other types of mills are used for fine level comminution or particle size reduction.

Type of Mill Media Size, in. Tip Speed, ft./sec. Ball mill ½ and larger ... 1. particle size reduction of chemicals; 2. mixing and milling of several chemicals

Besides particle size reduction, ball mills are also widely used for mixing, blending and dispersing, amorphisation of materials and mechanical alloying. [1, 49, 51]. As a construction, a ball milling device usually consists of a cylindrical vessel.

The Effect of Ball Size Diameter on Milling Performance ... it was observed that the particle size distribution when milling with 20 mm and the10 mm diameter balls

What particle size range does ball mill grinding . Ball mill grinding is one method of crushing ore to an appropriate size fraction. Specifically, ore is put into a ...

Mill (grinding) – Wikipedia, the free encyclopedia. These can be related to the Hukki relationship between particle size and the energy required to break the particles.

In this study, a computer simulation of a suitable matrix notation of the Broadbent and Callcott grinding model was written. First, a chromite sample was ground in ...

typical cement particle size out of clinker ball mill XSM is a leading global manufacturer of crushing and milling equipment (typical cement particle size out of ...

Correlation between process pameters and milling cutting tools. The WCpowders were found to have distinctly different particle size ... well as the kinetic energy of ...

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS François Mulenga Katubilwa ... Grinding rate versus particle size for a given ball diameter 25

HMK1901 Planetary Ball Mill. bigimg. ... HMK1901 Planetary Ball Mill is a convenient benchtop ball mill for size reduction and mixing purpose ... Particle Size ...

Rotary classifier mill; Ball mills; Particle size ... Particle Size Reduction British ... particle sizes to be achieved than with a conventional impact mill. Ball ...

Ball mill grinding is one method of crushing ore to an appropriate size fraction. Specifically, ore is put into a large receptacle (a drum) and then it rotat...

The latter equation is a generalization of the empirical law used in the definition of the competent ball size for a given particle ... size of ball is fed to the mill.

To the ore dressing plant, the working efficiency of ball mill is an important aspect of its operational efficiency. The qualified grinding granularity not directly ...

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

In materials processing a grinder is a machine for producing fine particle size reduction through attrition and compressive forces at the grain size ... Ball mill A ...

Paul O Abbé Equipment Company is a manufacturer of new Size Reduction Equipment such as Ball Mills, ... but will exhibit a narrow particle size ... Since mill ...

Such an increase of average particle size with increasing ball milling time has also been observed in lead zirconate titanate (PZT) aqueous suspension . 4.

Video embedded· Fritsch Planetary Ball Mills are perfectly designed for a ... Particle Size; Dividing Feeding; Lab ... Lab Synergy offers a complete line of mills and ...

WhatsApp)

WhatsApp)