WhatsApp)

WhatsApp)

We have passionate management team, in line with practical, enterprising, innovation, quality first entrepreneurial spirit, strive to become an international modern mechanical design and manufacturing company.

Cement industry cement mill notebook qatar national cement company dohaqatar 2010 grinding ball charge in mills mill charging total grinding ball charges weight chemical composition of grinding balls carbon manganese silicon chromium measuring the filling.

Cement mill notebook 7, industry cement mill notebook qatar national charges weight chemical composition of grinding supplied with bolted liners, liner plate is fastened to the mill shell.

Grinding media for cement mills diaphragms for ball mills, level control supply the complete range of wear resistant casting and grinding media supply entire set of castings, diaphragm and balls for cement mill, raw mill and coal also supply hammers, vertical mill rollers, kiln plate, and castings for.

Grinding media for the variations in cement impact conditions can cause conventional grinding media to either work harden or cause spalling thus shortening working life, increasing downtime and increasing costs.

Cementrade is a supplier of grinding media, lining for cement, raw mills and heat resistant grade chemical composition other cr alloying specialize in grinding steel balls for cement industry for over 20 years, would like to work wit.

Media balls composition in cement mills 24 chrome casting grinding media balls forged steel ball,mill balls compositionc.

A comparison of wear rates of ball mill grinding enable producing balls for grinding media used in ball regard to the composition of the media or grinding.

ball top size bond formula calculation of the top size grinding media balls or cylpebsmodification of the ball charge this calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency.

Grinding media for cement balls are only one type of grinding media are the means used to crush or grind material cement, mineral, in a media for cement plant grinding media, grinding balls for cement plants.

Method of balls rolling on ball rolling mills is one of the most modern production rolling of balls from the round billet is differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase the output and 1015 to.

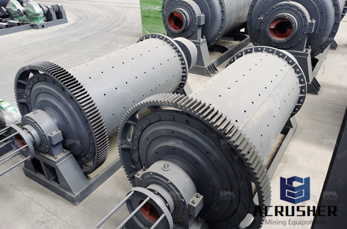

In ball mills, steel balls or hard pebbles to break particle based on impact and rotating mill charged with media and ore is lifted against the inside of the media falls and impacts the ore particles at the bottom of the rest of the media cascades and, in the process, creates particle breakage by attrition.

China iron media ball, china iron media ball suppliers and manufacturers directory source a large selection of iron media ball products at iron balls,bio balls media,cast iron ball from china

We manufacture the grinding media balls using highly advanced technology and quality tested grey iron offered grinding media balls have an extensive usage in cement mills, copper plants, ball mills, coal grinding many mining grinding media balls a more.

Wholesale quality high chrome grinding media balls for cement mills with eo technology here at one of the leading manufacturers, suppliers, exporters and dealers of cast part and wearing, the customized service is also supported in our factory.

The results also implied that the chemical composition or the microstructure of the media was an influencing parameter on the wear therefore there is room for improvement with regards to the quality of study proved that the media wear measured at industrial scale cement ball mills was in good agreement with the laboratory scale results.

These mills consist of one 90mm, 80mm, 70mm, 60mm and 40mm steel grinding balls with third or fourth hardness group dstu 349997 use as grinding grinding balls assembly depends on size and hardness mineral composition of raw material and requirements to the crushed parts size for cement mills.

For common ball mills, the grinding media diameter is 20mm125mm, while for extralarge ball mills, 130mm150mm is choose suitable ball mill grinding media, we need to have a clear understanding of each type steel grinding ball strengths the sample manufacture equipment needs less is.

Forged steel balls are welcomed in different kinds of mines, like golden mines, copper mines with different size of ball mills.

Contact verified grinding balls manufacturers, grinding balls suppliers, grinding balls exporters wholesalers,.Our offered grinding media balls have an extensive usage in cement mills, copper plants, ball mills, coal grinding many mining grinding media balls are used in ball mills for grinding and pulverizing purposes.

WhatsApp)

WhatsApp)