WhatsApp)

WhatsApp)

Then join our free live webinar on the new mixer mill mm 500 the first impact ball mill worldwide that efficiently grinds samples to nanosized particles with only minor warming new mixer mill mm 500 features a maximum frequency of 35 hz and is the.

The interplay between these forces produces the high and very effective degree of size reduction of the planetary ball international geardrive 4station planetary ball mills have builtin, reverse and timing energy ball mills grind down material to submicron level in minutes.

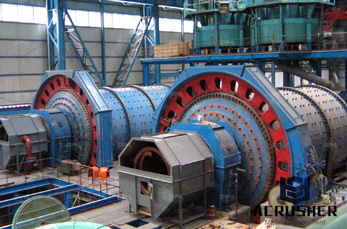

In the industrial departments such as metallurgy, building materials, chemistry, mining, power generation and ceramics, ball mill is an important machine for manufacturing powder the internal surface of the ball mill cylinder, there is often equipped with lining board with various surface lining board is one of the main easywearing spare parts of this grinding mill.

Ball mill is an efficient tool for grinding many materials into fine is widely applied to the production of cements, silicate products, building materials, fireproof materials, fertilizers, glass, ceramics as well as nonferrous and ferrous metal processing industries.

Common types of grinding mills include ball mills and rod includes all rotating mills with heavy grinding media article focuses on ball and rod mills excluding sag and ag their concepts are very similar, they are not discussed of a glass ended laboratory ball mill show action of ball mass within the mill.

Hari om, you are asking a question as to what are the characteristics of the ball ball mill the ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production line.

Structure of a ball about the structure of ball mill mining functions and structure of ball mill hongji mill is essential equipment for grinding after supplies are an efficient tool for grinding a variety of materials into powder.

Horizontal ball mill horizontal ball mill download 166 kb published date 2015 horizontal rotary miller used to grind the limestone rocks with metallic balls as grinding is used as the raw ingredient to produce cement unit of yfgw710 has integrated functions of backbone router, system manager.

Parts and their functions in ultrafine mill composition and production, need a lot of parts to cooperate, these parts play different roles in production, some in production, wear more serious, they belong to wearresistant parts, easy to be valued by people, such as bearings, grinding rolls, and other wear is not serious, so will be ignored, such as electric cabinet and so on.

Functions of ball mill lime handling plant in 120150tph station de concassage mobile de pierre de 120150tph station de concassage mobile de pierre de de concassage de minerai de fer du nouvelle guine 250tph station de concassage mobile.

Singlestage sag mills to the largest mill in the world with a 40foot diameter and 28 mw of motor mills ball milling is the most common application for horizontal tumbling offers a full range of ball mills to suit a wide variety of duties, from a few hundred kw all the way up to 20 mw and mills.

Effects of grinding media shapes on ball mill performance niyoshaka nistlaba stanley lameck a dissertation submitted to the faculty of engineering and the built environment, university of the witwatersrand, johannesburg, in fulfilment of the requirements for the degree of master of science in engineering johannesburg, october 2005.

Laboratory ball mill for sale brief introduction of laboratory ball mill vertical planetary ball mill is a necessary device of hightech materials mixing, fine grinding, sample making, new product development and small batch production.

Ball mill ball mill is a type of grinder used to grind and blend materials for use in mineral rock tumbler functions on the same ball mill is a key piece of equipment for grinding crushed materials, and it is widely used.

If a ball mill contained only coarse particles, then 100 of the mill grinding volume and power draw would be applied to the grinding of coarse reality, the mill always contains fines these fines are present in the ball mill feed and are produced as the particles pass through the mill.

Population balance model approach to ball size discretized selection functions are proportional to the specific power input to the mill, and the breakage functions can be taken as.

The cyclone mill tw100 is especially designed for food and feed sample is suitable for various analytical techniques, such as nir near infrared spectroscopy, kjeldl nitrogen determination, fiber determination and solvent extraction.

Grinding ball machine cnc lapping and polishing machine, find complete details about grinding ball machine cnc lapping and polishing machine,grinding ball machine,grinding machine,grinding machine parts and functions from supplier or manufacturershanghai nansen industry co., ltd.

A ball nose end mill, also known as a spherical end mill or ball end mill, has a semisphere at the tool nose end mills are used on workpieces with complex flat end mill ball end mill will determine the characteristics of the tooling marks or lack thereof on your model.

The planetary ball mill has functions of timing power off, selftiming forward and reversal may choose freely any operation modes of oneway direction, alternation, succession, time setting according to experimental needs, so as to improve efficiency of features of tencan ball mill low center of gravity.

In the 19th century roller mills were adapted to grist mills before replacing mill used either steel or porcelain the years 1865 and 1872, the hungarian milling industry upgraded and expanded the use of stone mills combined with roller mills in a process known as hungarian high milling.

The ball mill this can be caused for example by required inspections performed on the sag mill shell, bearings, etc., which leads to a relative short shutdown of the sag the ball mill would be equipped with fixed speed motors, then they will have to be washed out, isolated and stopped.

WhatsApp)

WhatsApp)