WhatsApp)

WhatsApp)

Grinding Efficiency Ball Mill, Wholesale Various High Quality Grinding Efficiency Ball Mill Products from Global Grinding Efficiency Ball Mill Suppliers and Grinding ...

PhysicoChemical Aspects of Grinding: ... energy input to the grinding mill. ... If this deformation energy is in. cluded, grinding efficiency can be considered

Factors Affecting the Efficiency of Ball Mill College Essays ... Ball mill is the key equipment for grinding after the crush process, and it is widely used in the ...

The energy efficiency of ball milling in comminution. ... data to provide an assessment of the energy efficiency of ... grinding efficiency (%) Fluid energy mill:

The ball mill crushes materials through the impact and grinding effect of the grinding media. In this process, the steel ball is used a medium of energy to transform ...

quality energy saving grinding mill_The Energy Story Chapter 12: Hydro Power The Energy Story is a general introduction to energy. Chapters explore renewable energy ...

On Jan 1, 2008 Burford (and others) published: Comparing energy efficiency in grinding mills

The Effects of Blasting on Crushing and Grinding Efficiency and Energy Consumption ... The role of different blasting energy input on fragmentation is

Energy Efficiency Comparison in Fine Grinding in the Mining Industry Michel Brissette,, Ing. VP Metallurgy ... energy efficiency than the ISA Mill

Achievement of High Energy Efficiency in Grinding Mills at CEEC. The relative ''efficiency'' of horizontal grinding mills compared to other comminution equipment is ...

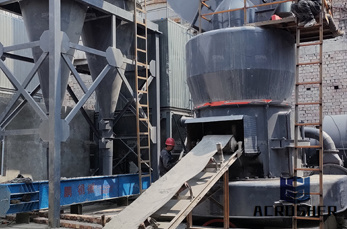

Mill (grinding)Wikipedia. A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cuttingTo calculate the needed grinding work ...

Mining on Top Stockholm. Stirred Grinding Mill Development and Application Expansion Gram Davey Process Manager Contents Current offering Efficiency and ...

Cement Mill/Final Grinding Process The ... uses a circuit grinding system where a high ... Company Toolkit for Energy Efficiency ...

ACHIEVEMENT OF HIGH ENERGY EFFICIENCY IN GRINDING MILLS AT SANTA RITA *S. Latchireddi1 and, E. Faria2 1OUTOTEC (USA) .

Better energy efficiency in the grinding process can bring significant cost savings to your concentration process. ... how to improve grinding efficiency of a mill ...

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle ...

Mill (grinding) Attrition Mill; A ... These can be related to the Hukki relationship between particle size and the energy ... the greater the grinding efficiency ...

Grinding Efficiency In Ball Mill. Size Reduction Equipment ... What is grinding efficiency? – ball mill. What is grinding efficiency? Energysaving Ball

Office of Energy Efficiency Renewable Energy. From Flour to Grits, ... You are here. Home » From Flour to Grits, a WaterPowered Mill Keeps on Grinding.

Outotec Grinding Mills. Optimize grinding mill ... TPL is an environmentally friendly technology used to achieve higher energy efficiency from the grinding mill.

Energy efficiency in grinding systems, Increasing Thermal Substitution Rate ( TSR) in Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant

IMPLEMENTING STRATEGIES TO IMPROVE MILL CAPACITY AND EFFICIENCY THROUGH CLASSIFICATION BY ... capacity and in energy consumption in closed grinding circuits is in ...

factors affecting the efficiency of hammer mill. Factors affecting size reduction,, hammer mill fluid energy mill energy mill etc Fluid classification methods ...

vibration energy grinding mill . media is the vibration mill. Typically this machine has one or two cylindrical grinding . by a free mill vibration with high ...

WhatsApp)

WhatsApp)