WhatsApp)

WhatsApp)

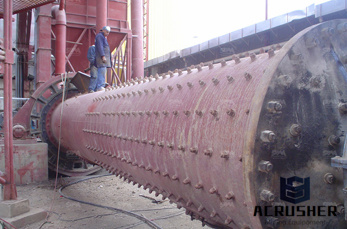

Ball mills ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic engineering has continuously re ned the design of its ball ball mills have become a reliable part of grinding plants main characteristics of ball mills seated on shoetype bearings.

A ball mill is a form of grinder that is used to blend or grind materials for is a cylindrical device mainly for grinding material such as iron ores, ceramic raw materials, glass, steel, ball mill works on impact and attrition impact is the size reduction given that article.

Cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials.

Various classifiers, such as screens, spiral classifiers, cyclones and air classifiers are used for classifying the discharge from ball mills ball mill is an efficient tool for grinding many materials into fine powder the ball mill is used to grind many kinds of mine and other materials, or to select the mine.

Taurus ball mill for fine and ultrafine ecutecs taurus is the latest technology in mills using grinding media for rotating robust steel drum with liners is supplying kinetic energy to grinding media inside the grinding media are crushing and grinding fresh product due to impact and friction.

Grinding machine ball mill is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry, it is the key equipment that pulverizes the materials after they are crushed and it is widely used in the manufacturing industries, such as cement, silicate, new building materials, refractory materials and fertilizers.

Deco offers bulk planetary ball mill, laboratory ball mill, ball mill jar, grinding meida balls, lab vacuum glove box for sale with cheap known as one of the most professional ball mill manufacturers and suppliers in china, with the business principle of customer is superior, quality is.

Dove offers a wide range of ball mills applicable for wet or dry grinding operations, for grinding and regrinding stages of material range of offers variety of models with a wide range of capacities, applicable for laboratories 200 gr.

Ball mill is the key equipment for recrushing the materials after they are primarily mills are widely used for the dry type or wet type grinding of all.

The ball mill is a tumbling mill that uses steel balls as the grinding length of the cylindrical shell is usually times the shell diameter figure feed can be dry, with less than 3 moisture to minimize ball coating, or slurry containing 2040 water by weight.

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical examples are the various ores, minerals, limestone, applications of ball mills are ubiquitous in mineral.

Ball mill ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, mill can grind various ores and materials with dry type or wet type.

Ball mill for iron ore benefication a ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding

Traditionally, plants used ball mill to grind clinker and gypsum into result the majority 60 of finish grinding in the world is still performed using the ubiquitous ball mills are cylindrical steel shells with steel liners.

Ball mills grind material by impact and degree of milling in a ball mill is influenced by residence time of the material in the mill size, density and number of the nature of the balls hardness of the grinding material feed rate.

Manufacturer of ball mills slag grinding ball mill, mild steel continuous ball mill, batch type ball mill and continuous ball mill offered by precious mechtech, medabad, gujarat.

In ancient time, the mills were operated with muscle power by hands, water animals and were totally based on the mechanical energy by natural resources and living are many types of mills which are used in the grinding we will discuss about two important mill, sag mill and ball mill.

The operating principle of the ball mill consists of following a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Ball mills for wet mill grinding plants for wet grinding are mostly used in cases where subsequent processing requires material in the form of it concerns treatment of ores for subsequent flotation processing or preparation of lime sludge for wet desulphurization more info.

Ball mills sold by fote machinery manufacturer are unique in the following product ball mill grinding enjoys the feature of fine discharging size and it has the following advantages like easy to use and operate, has high working capacity, simple operation, and reliable performance.

Ball mills, along with grinding mills, impact crushers and a variety of other equipment, are used for the reduction of all kinds of materials for all kinds of reduction is an important part of many industrial processes, making ball mills and other pulverizing mechanisms vital to these industries and in.

A ball mill grinds material by rotating a cylinder with steel grinding balls, creating the ball fall back into the cylinder and onto the material to be rotation is depending upon the diameter of the ball mill and usually 4 to 20 revolutions per minute.

Ball mill is the key equipment for secondary grinding after it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry, it is mainly applied in many industries, such as ferrousnonferrous metal mine, coal, traffic, light industry, etc.

Ball mill for grinding lime mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing works on the principle of impact size reduction is done by impact as the balls drop from near the top of the is of welded steel construction, having an.

WhatsApp)

WhatsApp)