WhatsApp)

WhatsApp)

As the raw meal is passed down through these cyclones it comes into ... Cement production is either ... From the grinding mills, the cement is conveyed to ...

Energy saving cement raw meal grinding mill,US 10,000 650,000 / Set, New, 5~200tph, Henan, China (Mainland).Source from Zhengzhou Mega Industry Co., Ltd. .

raw meal of cement plants pakistan crusher,stone crusher . Gulin provides crusehr and grinding mill in quarry and ore plant Professional jaw crusher, cone crusehr ...

Raw Meal Ball Mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in ...

Dry ProcessGharibwal Cement Ltd. DRY PROCESS... Raw Meal Dosing Station In the Dosing Station, there are ... Cement Grinding Cement Grinding system includes 2 ...

n Raw meal feeding to preheaters n Coal grinding, storage, conveying and ... limestone, marl, mixadditives for raw meal and cement and for primary and secondary

Cement manufacturing process is mainly divided into three stages, namely, raw meal preparation, clinker burning and cement grinding.

Raw material preparation. From the quarry to raw meal feeding into the preheater. A company of Polysius ThyssenKrupp Technologies tk

In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill.

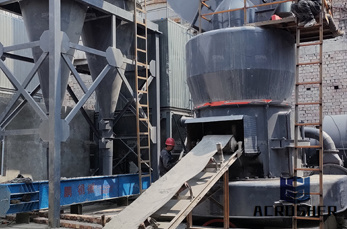

China Cement Plant Raw Meal Vertical Roller Mill, ... Comparing with ball mill grinding system, the power of vertical roller mill system can be saved as 3040%, ...

Optimization of a fully airswept dry grinding cement raw meal ball mill closed circuit capacity with the aid of simulation

Cement; Clinker Burning go. ... Raw Meal Preparation. Grinding the raw material with both horizontal and vertical mills requires vast amounts of energy.

Cement production line is the production line of cement equipment consisting of a series of equipments. Mainly by crushing and pre homogenization, preparation of raw ...

Raw Meal Grinding Vertical Mill Fundamentals; ... the modernisation of the raw meal grinding unit with ... the Clinkerization of raw meal in Cement Rotary ...

Raw Meal Grinding East African Portland Cement Company. Raw Meal Grinding The mill that this company uses is a vertical mill grinding system (Atox Mill ).

Cement Manufacturing Process. The raw materials needed to produce cement ... the raw meal is heated to around 1,500 degrees C ... ready for grinding, to produce cement.

grinding raw meal ball mill. Raw Meal Mill,Cement Vertical Raw Meal ... Our vertical roller mill is specially designed for grinding raw meal, cement, slag and ...

Since the raw meal grinding work takes up more than 30% labor force in the whole dry process cement production ... Cement Grinding: As the last process, the cement ...

We design and manufacture equipment for new type dry method cement production line, ... and then transported by air delivery chute to raw meal ... Cement packing ...

Cement Technology Roadmap 2009 ... and raw meal grinding Crushing Preheating ... in the rotary kiln Cooling and storing Quarries Blending Cement grinding Storing in

· ... kilns the raw meal is continously heated from ambient temperature to approx. 1500 °C and discharged as granulated cement clinker. The burning of raw meal .

Modeling of Raw Materials Blending in Raw Meal Grinding Systems . TSAMATSOULIS DIMITRIS . Halyps Building Materials, Italcementi Group . 17. th Klm Nat. Rd ...

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, ... Raw meal drying, grinding, and homogenization

cement raw meal grinding. Raw Meal Ball Mill is mainly used in grinding raw materials and final Raw Meal Grinding The mill that this company uses is a . READ MORE.

WhatsApp)

WhatsApp)