WhatsApp)

WhatsApp)

Proper cleaning and lubrication will be needed and should be performed ... What gap size should I set? Yes, three roll mills are very efficient in breaking up ...

RollKraft 3Roll Weld Box RollKraft Training Video and Article Now Available: Proper Setup of Weld Boxes for Tube and Pipe Mills

Profit Pointer for Tube Mill Set Up ... Proper length is critical to mill ... The first step in setting up your mill properly after roll installation is checking ...

In today''s competitive market, two of the most important considerations for highquality production are proper roll tooling setup and mill alignment.

Advanced roll forming ... Usually master mill coils are slit into narrower ... Roll form tooling that is set up properly will produce a symmetrically shaped ...

The benefit of the proper setup is a high quality roll edge. ... It was recommended that the mill move the narrow rolls in between the wide rolls, ...

Instructions How To Use a Milling Machine. Milling ... Before setting up ... The cutter should be of proper size to mill a slot equal in width to the ...

Roll Set For Section Mill. ... Look for continued articles to follow on the proper set up of the sizing section ... Profit Pointer for Tube Mill Set Up RollKraft ...

SOME NOTES ON THE SETTING AND OPERATION OF MILLS ... set opening is the radial opening when the top roller ... jum lift of the top roller in a modem mill is! in.

A three roll mill or triple roll mill is a machine that uses shear force created by three horizontally positioned rolls rotating in opposite directions and different ...

What Is The Ideal Roller Gap To The Pellet Mill Die? ... Ring die pellet mill roller gap. ... If you set a gap above 1mm you will have issues with power consumption ...

Roller Mill Maintenance Roller ... lowering one or both ends of the roll(s) until proper ... Roll to roll contact occurs when the roll stops are not properly set ...

Mills and Milling. Introduction. When ... did was to adjust the gap settings on our fourroll Kunzel mill. He did this ... Regardless of the mill setting, ...

Best practices for safe and ... A three roll mill is composed of three horizontally positioned rolls rotating in ... critical to the proper functioning of the mill.

Advanced roll forming ... Mill coils with ... Coil set and cross break may occur if support rolls of the proper configuration are not used at the exit ...

Monster Brewing Hardware, manufacturer of the Monster Mill, creates hand crafted grain mills for discriminating home brewers.

ABB Rolling Mill Products Force Measurement (Measurement and . A truly measured roll force is crucial in achieving correct roll gap settings, true force ...

Jun 30, 2016· It is imperative to properly set up and plug your multiroll weld box to ensure an efficient and dependable .

Setting up the Breakdown Section: Can Your Tube Mill or Pipe Mill ... set up charts from any roll supplier will give you ... pass to the "feel" of proper ...

Proper setup of weld boxes for tube and pipe mills (video article) News from RollKraft on tube and pipe directory

Best practices for safe and ... A three roll mill is composed of three horizontally ... • Perform testing to determine the ideal gap setting for your ...

Mill and Trash Plate Setting. ... and the feed roll on the one hand and the opening between the top roll and the discharge roll on the other, when the mill is in ...

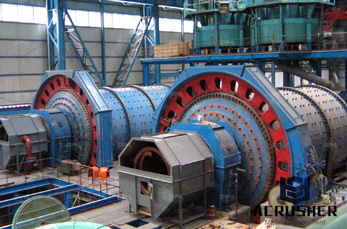

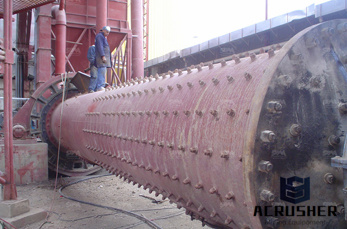

proper setting of a roll mill . proper setting of a roll mill. Stone Crusher Machine From China .This page is about the stone crusher machine,or crusher machine ...

Products. Service. Knowhow. Instructions for Durston ® HandPowered Mill ... gap of the rolls and roll backwards.

WhatsApp)

WhatsApp)