WhatsApp)

WhatsApp)

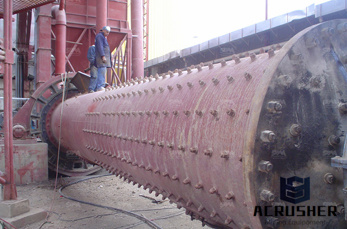

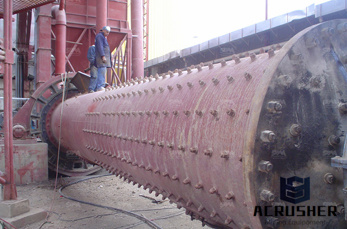

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

Manufacturer of grinding pulverizing ball mill balls grinding balls made of alumina ceramic products, alumina, ceramic materials, porcelain, zirconium oxide zirconia dispersion bead cylindrical alumina grinding media.

The steady state ball size distribution in the mill depends on the topup effect of the ball size distribution on the milling rate of coal has been measured as a function of ball size change in ball size distribution as affected by wear and ball topup policy has been modelled.

N2 in this article, alternative forms of optimizing the milling efficiency of a laboratory scale ball mill by varying the grinding media size distribution and the feed material particle size distribution were ore was used as the test material.

Grinding media grinding media are the means used to crush or grind material in a comes in different forms such as alumina oxide balls, ceramic cylinders, or soda lime norstone inc., we offer all types of medias used for grinding, deagglomeration, polishing, deburring, fillers, proppants, spacers, refractory beds and shot peening.

Application energy saving mining ball mill is a key equipment in beneficiation is widely used in ore dressing production line such as gold ore, cooper ore, magnetite ore, antimony, calcite, kaolin, mica, clay, bentonite etc ferrou metal or nonferrous metal materials.

Grinding media size effect the ability to operate a mill with smallerdiameter grinding media greatly increases the mills efficiency and can overall further increase the quality of product through finer, smaller grinding beads are more prone to hydraulic packing due.

Sino grinding international sgi is a global company specializing in the design, manufacturing and distribution of grinding regional marketing offices offer regular onsite technical and logistical support.

The objective of this study is to investigate the effect of ball proportion on the grinding kinetics of cement clinker in a horizontal planetary grinding media proportions used for the tests were,,,16.

Mill type types of mill design are overflow discharge mill is best suited for fine grinding to 75 106 diaphram or grate discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 250 centerperiphery discharge mill has feed reporting from both ends and the product discharges.

Grinding is the process of achieving particle size reduction through attrition and compressive forces at the granular grinding media in a ball mill is typically steel or ceramic balls of varying sizes, depending on the feed size, work index of the ore and the size reduction and distribution.

Mill, media the grinding media used are, generally, balls and compartments of coarse and medium grinding are used balls, and in that of fine grinding, balls or any compartment, sizes of grinding media must be correlated with the size of the the balls are formed free spaces emptiness.

In this article, alternative forms of optimizing the milling efficiency of a laboratory scale ball mill by varying the grinding media size distribution and the feed material particle size distribution were ore was used as the test material.

Trajectory analysis to optimise grinding action and minimise ballliner the charge motion to ensure grinding media is hitting the toe of the charge will result in the maximising of ore breakage rates and therefore mill throughput.

Make sure that the shot is designed as a grinding media or it could tear up the shot is one of the least expensive grinding medias with the benefit of high density and the availability of a wide range of sizes for small more narrow size ranges of shot will last longer.

Of grinding media in ball mills for both friends, can you tell me anybody about how much of grinding media required for firstsecond chambers ball to clinker ratio for cement grinding with 3000 to estimate the of grinding media with empty height.

Cement mill grinding experts, i want to know about the gm size wise percentage distribution in a 2 chamber close circuit opc ball x load 128 mt high let me know how do the supplier selected 80mm as size in this mill please share the formula as well.

Calculation of grinding media in ball mill clinker,calculation of top size grinding media fred c bond calculation of top size grinding media azzaronis formula if you calculate from figure 5 assuming you wanttarget a p90 of 60 microns you get around 22 mm 1 inch as a ball size this is quite the difference optimal ball diameter in a mill grindingoperationsdesign preferred size of balls for.

Characteristics of the grinding media mass, density, ball size distribution speed of rotation of the mill slurry density in case of wet grinding estimations of these parameters can be found in 4, 5, important characteristic of an industrial ball mill is.

Japans largest platform for academic ejournals jstage is a full text database for reviewed academic papers published by japanese societies.

The mill is equipped with a discharge diaphragm at the diaphragm retains the grinding media in the second chamber and allows the discharge of finely ground circuit ball mill, gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement.

The role of grinding media ball in media ball have a significant impact on the performance of grinding mills in terms of product size distribution, energy consumption and grinding below figure shows main grinding costs for the specified mills.

Grinding media grinding media are the means used to crush or grind material in a comes in different forms such as alumina oxide balls, ceramic cylinders, or soda lime norstone inc., we offer all types of medias used for grinding, deagglomeration, polishing, deburring, fillers, proppants, spacers, refractory beds and shot peening.

Alukingalumina grinding media aluking 92 alumina grinding size range and narrow size distribution contributing to higher productivity in grinding and dispersion wear resistance resulting in minimizing product contamination from media wear and less frequent media ball mill ppmh.

WhatsApp)

WhatsApp)