WhatsApp)

WhatsApp)

Mill in liners plate design calculation in cement 120150tph station de concassage mobile de pierre de 120150tph station de concassage mobile de pierre de de concassage de minerai de fer du nouvelle.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or comminution is an important unit operation in many are many different types of mills and many types of materials processed in mills were powered by hand, via a hand crank, working animal

No matter what type of material has to be ground cement raw material, cement clinker or granulated blastfurnace slag and how different their grindability and abrasiveness may be, the mvr mill ensures throughput rates of a different dimension, around the clock, reliably and on.

The ok mill design uses the same swing lever and roller assemblies for either cement or raw also allows the ability to continue using the unique grinding roller profile of the ok cement mill and an optimised spherical grinding profile for raw grinding rollers are in a lifted position when the mill is started,.

Raw mill cement liners raw mill shell liners suppliers crushergoogle high cr mill liners for cement mill, list of mill liners raw material suppliers,.Get price and support online cement industry reliance steel offer parts for raw mill.

Cement industry cement mill notebook qatar national cement company dohaqatar 2010 fineness of the material at the mill outlet depends mainly on the retention time of the material in the main influencing factor on the retention time is the mill worn out liners in a cement mill.

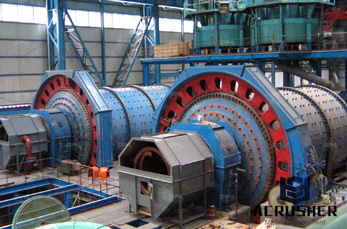

Traditionally, plants used ball mill to grind clinker and gypsum into result the majority 60 of finish grinding in the world is still performed using the ubiquitous ball mills are cylindrical steel shells with steel rotating drums.

Mvr vertical roller mill with planetary gearbox mvr vertical mill with conventional drive economical solution for small to medium output rates for the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the mvr mill with conventional drive is.

Wear method for lining plate of cement ball millraymond cement ball mill equipment is an indispensable part of the cement mill grinding and flour separation equipment, but in the process of using the cement ball mill, many users reflect that after a period of time, the liner of the cement ball mill will be worn and often stopped to replace the.

Find here information of mill liners selling companies for your buy verified mill liners manufacturers, mill liners suppliers, mill liners exporters wholesalers, producers, retailers and.

Combination linings combine the advantages of steel lifters with moulded wear resistant rubber liners have been used for many years in tough applications in up to 28 ag mills, sag mills, or primary ball mills using plus 3 inch mill central mill rubber pulp mill.

Mill in liners plate design calculation in cement in liners plate design calculation in cement plant mill in liners plate design calculation in cement pulverizer or grinder is a mechanical device for the grinding of many different types of materials.

Cement ball mill liners offered by ganesh loco components private available with multiple payment options and easy site uses using our site you agree to our privacy closing this banner, scrolling this page, clicking a link or continuing to browse otherwise, you agree to the use of cookies.

The design of a ball mill can vary significantly depending on the size, industrial applications, the inner surface of the mill is lined with mill liners protecting the steel body of the mill and incorporating mill lifters which help to raise the content of the mill to greater heights before it work index of the material.

The cement clinker grinding circuit reduces the feed from 80 passing size between 10 and 20 mm to 100 passing 90 size reduction takes place in a two compartment tube mill the first compartment of the mill is shorter than the second compartment.

Description trunnion liners are potential failure points in the mill protect the inside of trunnions from the abrasive action of the material liners can lead to erosion of the trunnions, mill head, and fit the erosion is stopped, form loose liner prefabricated industry application crushers grinding mills, mining, pipes piping.

Some grinding balls of this material have been applied in the power plant coalgrinding mill of in diametr and in length, and the cement grinding primary mill of.

Abrasion is the most dominant factor in determining the working life of vertical mill grinding elements and the group supplies three types of alloy to cope with the different abrasion line with the trend towards ever larger mills, the company can produce individual castings of.

Cement has been developed in collaboration with industry leading mill oems and experts in material science to ensure optimum millcarb, we enter a new era of wear protection for mill grinding components and set new standards in the cement fully repairable welded ceramic composite metal.

Cement grinding mill authorstream summary material level material level ball level over the entire compartment ball charge classification progressive decrease of the ball size in c2 diaphragm slots first compartment slots 6mm to 8mm second compartment outlet slots larger by at least 2mm than those of first compartment ventilation screens they have to have the.

A cement mill or finish mill in north american usage is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball china ball mill grinding, ball mill grinding.

Study of material mating for grinding balls and liners in ball mill selection of wearresistant liners of cement mill selection and application of ball mill liners.

Cement international newly developed mvr roller mill for grinding cement raw material, cement clinker, and additives with an roller mill, ball mill and 1 layout and aerial view of the balaji

WhatsApp)

WhatsApp)