WhatsApp)

WhatsApp)

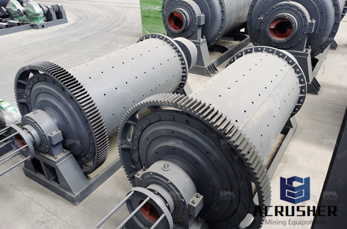

Used Polysius for sale. Krupp and more. Machinio... design air flow is 98,000 acfm, motor power is 300 hp and variable speed drive, ... POLYSIUS; ball mill polysius 17250 x 4600 mm used machine item size: ... >> Get Price Used ...

Improving Energy Efficiency in SAG Mills (pdf) Online SAG Mill Grinding Pulse Measurement and Optimization Blast Fragmentation for Maximising the Sag Mill Throughput at Porgera Gold Mine Variable Speed Control of SAG Mill ...

Case note ACS 1000 variable speed drive increases output and performance of SAG mill LaRonde mine AgnicoEagle''s LaRonde mine has a large goldsilverbase metal deposit and contains the largest reserve resource base of any ...

Ball Mill Help? You could use a heavy duty,variable speed, high torque drill as a direct drive motor or possibly a motor from an old washer or drier with a pulley setup. » Learn More SAG Mill Success—Start with ...

ABB''s Gearless mill drive system is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills ... Our GMD eliminates all mechanical components of a conventional mill drive ...

2017/08/13· [Show abstract] [Hide abstract] ABSTRACT: The various options available for larrsepower semiautogenous grinding (SAG) mill drive systems are examined, together with their impacts on mill design and relative capital ...

A control strategy recently implemented on a large variablespeed SAG mill at MMG''s Century Zinc operation in Australia is shown in the chart (found on pg. 32). In this case, mill speed is the primary manipulated variable used to control ...

Description: 16 ft. x 30 ft. Vecor SAG Mill Available as is or fully refurbished complete with: – Refurbished mill shell, 6mm rubber lined, drilled for steel lining – Refurbished mill ends, 6mm rubber lined, drilled for steel liners ...

With the proven use of gearless drive technology, the limitation of AG/SAG mill size due to gearing constraints has been eliminated. is the world''s leading supplier of gearless AG/SAG mills.

MOTOR TECHNOLOGY Saving energy TMEIC torques can be produced at low speed ... • Mills that require variable speed operation ISaving energy ... typical SAG ... Belt Drives and Chain Drives es for Mott, 2002 and Kurtz, 1999 ...

IEEE TRANSACTIONS ONINDUSTRY APPLICATIONS. 26. SEPTEMBER/OCTOBER VOL. 1990 901 Selection Criteria for Sag Mill Drive Systems STEPHEN A. GREER, SENIOR MEMBER, EEE I Abstract Tbe various ...

Mill operating conditions including mill speed (for circuits with variablespeed drives), density, and total mill load The effect of feed hardness is the most significant driver for AG/SAG performance: with variations in ore hardness ...

2 SINGLE STAGE SAG/AG MILLING DESIGN ABSTRACT Single stage semiautogenous / autogenous (S/AG) milling has become a common design for a variety of ore types with the advantages of being comparatively low capital ...

2 | Model Predictive Control for SAG Milling in Minerals Processing Ore from primary crushers is combined with water in the mill where rotation causes the grinding media and the ore to be drawn upwards with the mill liners and ...

SAG Mill Success—Start with the Basics womp . SAG Mill Control: It Shouldn ... the load in the mill by adjusting the feed rate of ore to the mill and ... on a large variablespeed SAG mill at MMG''s Century Zinc ... >Chat now

Exceeding your performance limits SmartMill combines a variablespeed drive system with advanced process control to provide maximum mill control. It can be applied to new or existing AG, SAG and ball mills, powered by either ring ...

ball mill variable speed drive Copper Mountain: Overview on the grinding mills and . SAG mill, ball mill, ring gear, dual pinion, drive systems, variable speed The grinding circuit consists of a ... Get Price Online

Overview on the grinding mills and their dual pinion mill drives mill and two 24'' x '' ball mills will be briefly discussed. ... SAG mill, ball mill, ring gear, dual pinion, drive systems, variable speed ... Ore product size P80.

2 d4 TM Mill Drivesystem 7 MW 7 MW 14 MW 28 MW 7 MW 4 MW 7 MW 7 MW 7 MW 4 MW 7 MW 7 MW SAG mill 32 ft. single drive The natural progression in gear/pinion mill drives: The QdX4TM Mill Drive provides ...

For a conversion of mill lining from polymet to steel; What effects will there be on power draw, grinding or other operating/performance variables? I am looking at the possibility of converting a steel/rubber hybrid AKA Polymet lined SAG ...

variable speed capability comes with the drive as an inherent feature. Due to the investment cost the ring motor drive is usually applied for drive powers above 10 MW. Shellsupported grinding mills offer special benefits to ring x ...

The Hyper SER Drive can transfer to fixed speed mode during undervoltages, then transfer back to variable speed when the supply voltage stabilizes, ensuring no costly mill stops occur." SAG mill breakdowns are costly events for ...

TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS MILL DRIVES FOR GRINDING APPLICATIONS M. rens, ABB, Switzerland J. Gonser, ABB, Switzerland Abstract Gearless mill drives are a well establishedas their ...

The mill is driven by two GE horizontal synchronous variable speed motors, one of which is depicted on the bottom right. SAG mill feed is conveyed from the coarse ore stockpile. The ore passes through a gyratory crusher where. ...

WhatsApp)

WhatsApp)