WhatsApp)

WhatsApp)

Effect of Slurry Solids Concentration and Ball ... utilize the available mill capacity and maintain energy efficiency for these ... ball mill at different operating

cataracting in ball mills Grinding Mill China. cataracting cascading cement mill howShanghai Caiman Machinery . Grinding Mill. MTM medium speed trapezium mill ...

Comminution efficiency is a technical term that relates some measure of the output from a comminution machine to the energy input into it. The term has usually been ...

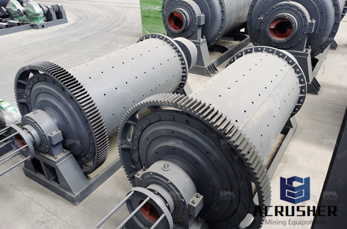

What Is Ball Mill And Its Working Principle? The usage of ball mill and its technical data Ball mill is widely used for grinding ores and rocks in metal and nonmetal ...

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

not meet design throughput at the design operating conditions of ball and rock charge, ... Ø SAG mill efficiency was highly dependent on recycle crushing.

operating ball mill efficiency. The determination of the efficiency of the milling process SAIMM. parison with ball milling results thus yields a value for the ...

Cement grinding Vertical roller mills versus ball ... The twocompartment ball mill operating in a closed circuit with a ... efficiency separator the OK mill, ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

Ball Mill. Ball mill and rod mill is very good for grinding ore into fine dust particles. However, improved efficiency, largescale mining projects, including the ...

Easy Operating Ball Mill, Wholesale Various High Quality Easy Operating Ball Mill Products from Global Easy Operating Ball Mill Suppliers and Easy Operating Ball Mill ...

CALCULATION OF BALL MILL GRINDING EFFICIENCY International . Please can anyone give me, step step by procedure on how to work out on cement ball mills to. .

The harder the media the better the grinding efficiency and consequently, ... The theoretical critical speed of a ball mill is the speed at which the centrifugal ...

Why is the Bond Ball Mill Grindability Test done the way it is done? Man ... My experience has shown that the Bond mill, operating at the condition specified by Bond

Grinding Efficiency + Pdf. ... ball mill grinding efficiency ... design variables and operating conditions related to ball mill grinding efficiency.

1 Metallurgical Plant Design and Operating Strategies (MetPlant 2013) 15 17 July 2013, Perth WA Energy Efficient Ball Mill Circuit – Equipment Sizing

The specific selection function effect on clinker grinding . efficiency in a dry batch ball mill . ... observations showed that ball diameter, as an operating ...

SGS MINERALS SERVICES 2001 ApplicAtion of operAting Work indices to evAluAte individuAl sections in Autogenous semiAutogenous/BAll mill circuits

THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 89 Pilot plant description The milling pilot plant consists of two .

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager Salt River .

Reverse spiral impeller, returns the steel ball and coarse ore to ball mill. High efficiency and energy saving, self discharging, fine grinding size

diameter on the operating parameters of the mill, ... energy efficiency, the power requirement, mill load, ... size ball mill was used with ball media of sizes 10 ...

Ball Mill Bb27 Operating Manual. Zenith crushing equipment is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher and ...

WhatsApp)

WhatsApp)